Application Background and Engineering Context

PROFINET IO absolute encoders are a fundamental component in modern industrial automation systems where deterministic communication, real-time position feedback, and seamless integration with PLC-based architectures are required. As Ethernet-based fieldbus systems increasingly replace traditional serial communication protocols, PROFINET has become a preferred choice for motion-related applications that demand high synchronization accuracy and network transparency.

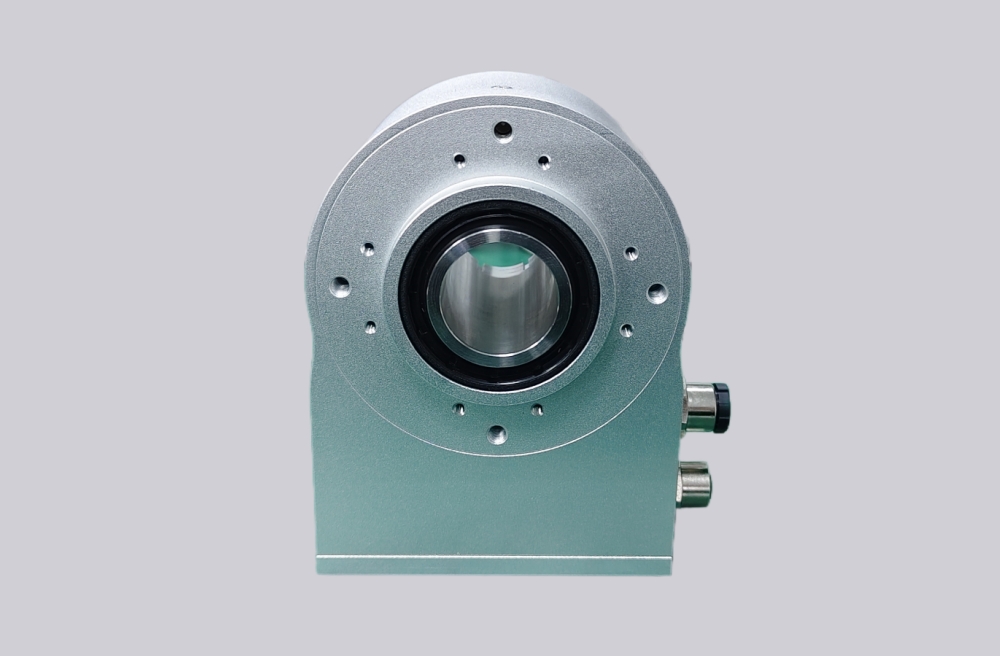

In standard industrial environments, compact encoder designs in the 58 mm class are widely adopted due to their balance of mechanical compatibility, communication performance, and installation flexibility. These encoders are commonly integrated into machines where space constraints, modular design principles, and standardized components play an important role in overall system architecture.

Typical Applications for Standard-Housing PROFINET Encoders

Standard-housing PROFINET IO absolute encoders are typically used in applications where reliable position feedback is required without exposure to extreme environmental or hazardous conditions. Common application areas include:

- Automated production and assembly lines

- Packaging and labeling machinery

- Conveyor and material handling systems

- Printing, textile, and woodworking equipment

- General-purpose motion control axes

In these applications, the encoder often operates as part of a distributed automation system, communicating directly with a central PLC while coordinating with drives, sensors, and I/O modules over the same PROFINET network.

Mechanical Design and Installation Flexibility

A key advantage of standard-housing PROFINET absolute encoders is their mechanical versatility. Typical designs support both solid-shaft (clamping flange) and blind hollow-shaft (through-bore coupling) configurations, allowing engineers to select the most suitable mounting method based on machine design and installation constraints.

- Solid-shaft designs are commonly used in new machine builds where flexible couplings or belt-driven mechanisms are employed.

- Blind hollow-shaft designs simplify alignment and reduce installation effort in compact assemblies or when replacing existing encoders.

This flexibility makes 58 mm class encoders particularly suitable for OEM equipment and modular machine platforms where mechanical standardization is a priority.

PROFINET IO Communication Characteristics

From a communication perspective, PROFINET IO provides cyclic real-time data exchange for motion-related information while also supporting acyclic access for diagnostics, device identification, and parameterization. This dual communication mechanism allows position data to remain tightly synchronized with the automation process while enabling maintenance and configuration tasks without interrupting operation.

In standard industrial automation systems, PROFINET encoders typically operate within RT (Real-Time) communication classes, which are sufficient for most positioning and speed feedback applications. Integration into PROFINET networks also enables features such as:

- Device naming and topology recognition

- Centralized diagnostics via PLC or engineering software

- Simplified commissioning through standardized Ethernet infrastructure

System Integration and PLC Compatibility Considerations

When integrating a PROFINET IO absolute encoder into a control system, engineers should consider not only the encoder itself but also the overall network architecture. Factors such as network topology (line, star, or ring), cable routing, and controller performance can directly influence system reliability.

Standard-housing PROFINET encoders are commonly used with mainstream PLC platforms in centralized or distributed automation concepts. Their Ethernet-based communication allows them to coexist with other PROFINET devices on the same network, reducing wiring complexity and improving system scalability.

Proper planning of IP addressing, device naming, and diagnostic access is essential during commissioning to ensure stable long-term operation.

Environmental and Reliability Considerations

Although standard-housing PROFINET encoders are not intended for hazardous or explosive environments, they are designed to withstand typical industrial conditions such as vibration, dust, and moderate temperature variations. In many applications, long-term reliability depends more on correct installation and cable management than on extreme environmental ratings.

Engineers should pay particular attention to mechanical alignment, strain relief for Ethernet cables, and proper grounding practices. These factors play a critical role in maintaining signal integrity and minimizing downtime in Ethernet-based automation systems.

Common Selection Pitfalls and Engineering Notes

In practice, several recurring issues can affect encoder selection and system performance:

- Selecting Ethernet-based encoders without considering network load and real-time requirements

- Over-specifying resolution without accounting for mechanical backlash or system dynamics

- Neglecting mechanical installation tolerances, leading to premature bearing wear

Understanding these factors during the early design phase helps avoid unnecessary complexity and improves overall system robustness.

Engineering Next Steps

Once the communication protocol, installation method, and operating environment have been defined, engineers should proceed with detailed verification of mechanical dimensions, electrical interfaces, and system compatibility as part of the final design and procurement process.

Technical Reference

For engineers who require detailed specifications, configuration options, and mechanical drawings, the corresponding PROFINET IO absolute encoder documentation provided by the SIVIDI technical team can be used as a technical reference during final selection.