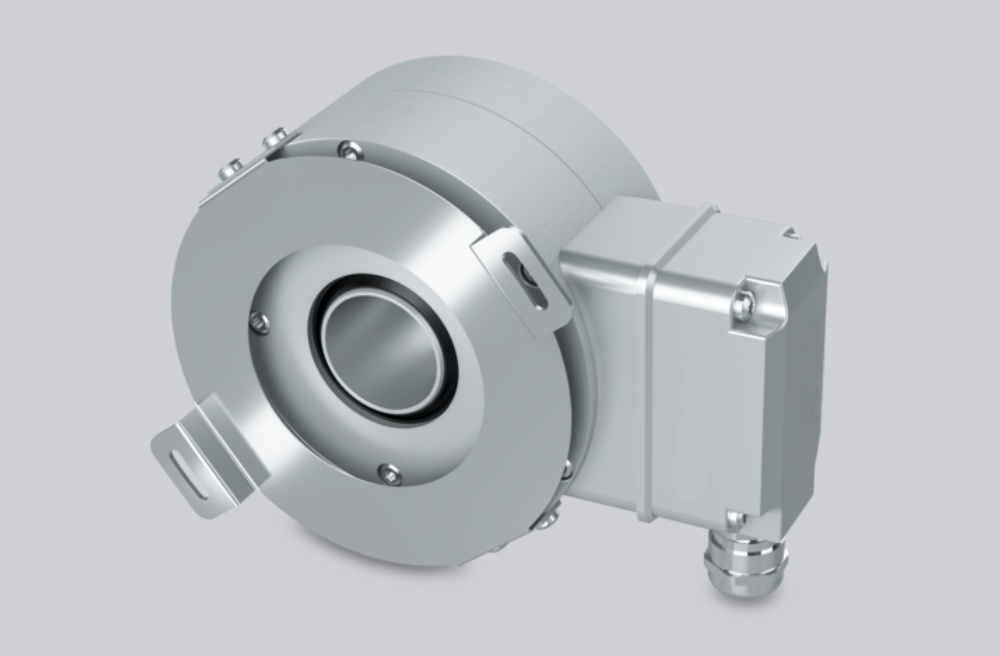

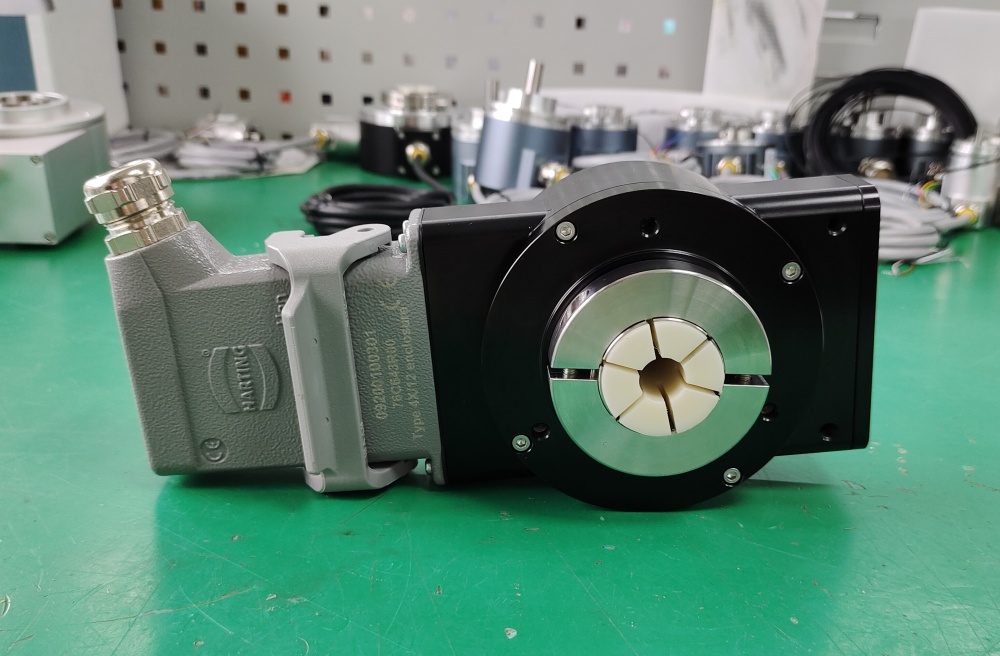

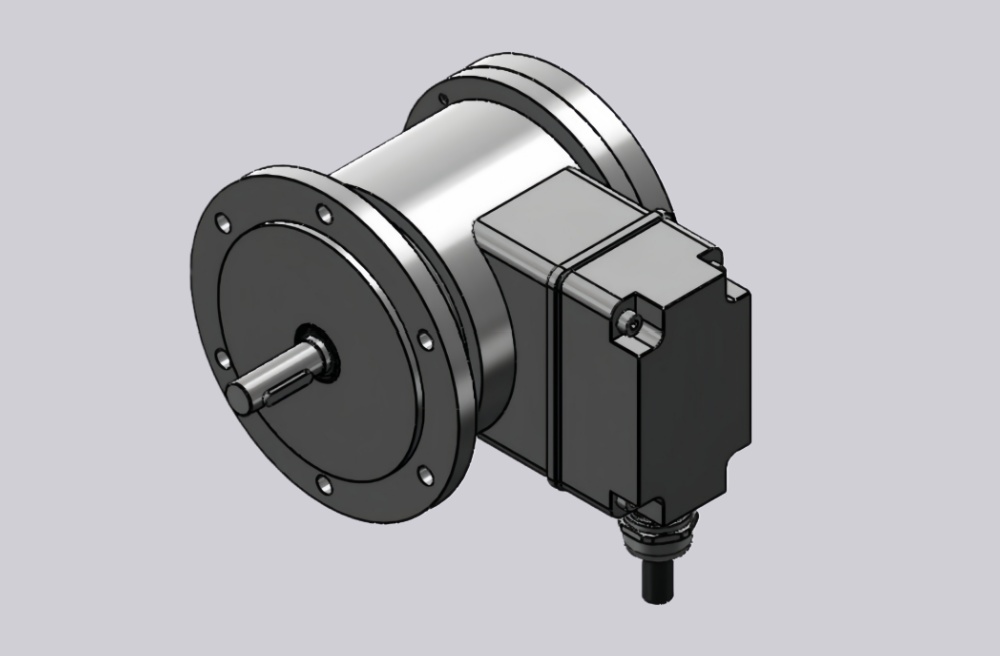

For applications requiring the POG10 D 1024 I encoder, we provide a proven and reliable customized replacement solution. The replacement encoder is engineered to match the original model in mounting interface, shaft configuration, resolution, output signal type, and key electrical characteristics. It can be installed directly in existing systems without changes to the control program or system parameters, making it suitable for continuous operation and heavy-duty industrial environments.

From a technical perspective, this model is a heavy-duty incremental rotary encoder with a resolution of 1024 pulses per revolution, providing A/B/Z incremental outputs with index pulse (I signal). The replacement solution ensures equivalent signal integrity, phase accuracy, and response frequency, meeting standard requirements for position and speed feedback in industrial automation systems. Output levels such as HTL or TTL can be configured as required, while supply voltage range and electromagnetic immunity are designed to support stable operation under high-speed rotation, long cable runs, and electrically noisy conditions. Robust internal bearing systems and reinforced mechanical structures are applied to withstand high shaft loads and frequent start-stop cycles.

In terms of mechanical compatibility and environmental performance, the replacement encoder can be customized according to the original shaft diameter, tolerance class, flange dimensions, and protection level. It is fully compatible with common solid-shaft installations and is widely applicable in steel and metallurgical equipment, cranes, conveyors, heavy machinery, and energy-related systems. Through application-specific parameter confirmation and pre-delivery testing, this customized replacement solution offers dependable long-term performance, simplified maintenance, and optimized lifecycle cost, making it a practical and trustworthy alternative for the POG10 D 1024 I encoder.

Technical data

| Parameter | Value |

| Technical data - electrical ratings | |

| Voltage supply | 5 VDC ±5 %; 9...26 VDC; 9...30 VDC |

| Consumption w/o load | ≤100 mA |

| Resolution (steps/turn) | 1...2500 |

| Phase shift | 90° ±20° |

| Scan ratio | 40...60 % |

| Reference signal | Zero pulse, width 90° |

| Sensing method | Optical |

| Output frequency | ≤120 kHz |

| Output signals | K1, K2, K0 + inverted |

| Output circuit | TTL (RS422); HTL (power linedriver) |

| Interference immunity | DIN EN 61000-6-2 |

| Emitted interference | DIN EN 61000-6-4 |

| POG 10 (Approval) | |

| Approval | UL approval / E256710 |

| Technical data - mechanical design | |

| Dimensions (flange) | ø115 mm |

| Shaft | ø11 mm |

| Shaft loading | ≤300 N axial; ≤450 N radial |

| Flange | EURO flange B10 |

| Protection DIN EN 60529 | IP 66 |

| Materials | Housing: aluminium die-cast; Shaft: stainless steel |

| Operating temperature | -40...+100 °C; -50...+100 °C (optional) |

| Connection | Terminal box |

| POG 10 (Mechanical) | |

| Operating speed | ≤12000 rpm (mechanical) |

| Operating torque typ. | 2 Ncm |

| Rotor moment of inertia | 200 gcm² |

| Resistance | IEC 60068-2-6 Vibration 20 g, 10-2000 Hz; IEC 60068-2-27 |