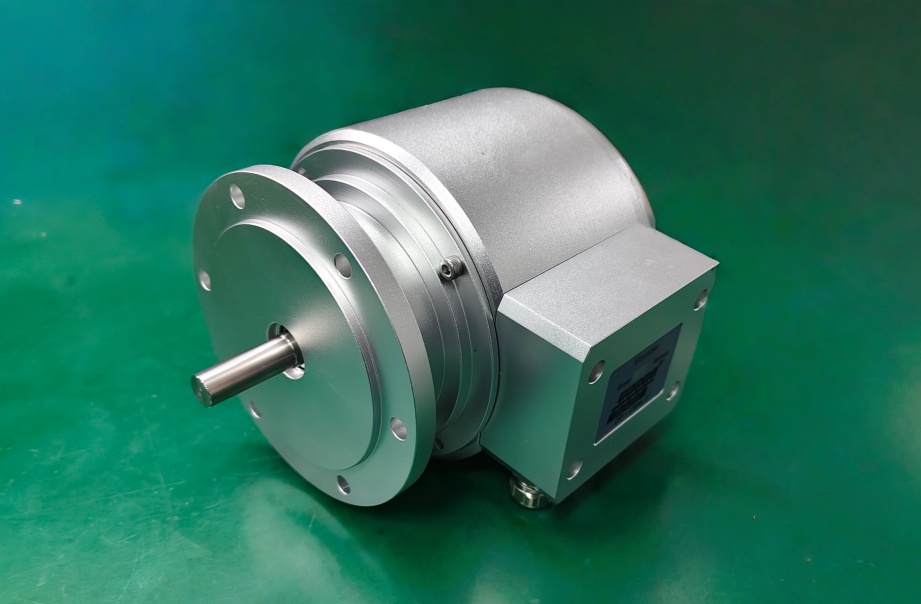

We provide a customized 1:1 replacement solution for the PMG10 P17-013-01 Profibus-DP encoder, designed to match the original electrical characteristics, communication behavior, and application performance. This replacement option is intended for seamless integration into existing automation systems without changes to PLC configuration, bus topology, or control logic, making it suitable for retrofit and system upgrades.

The encoder is based on a robust optical sensing principle and supports Profibus-DP communication, ensuring stable cyclic data exchange and deterministic real-time performance. It is well suited for industrial environments such as drive systems, material handling equipment, and process automation where reliable position feedback is essential. The device supports industry-standard voltage supply ranges and complies with EMC requirements for industrial networks, providing high immunity to interference and consistent signal integrity on the fieldbus.

Our replacement solution focuses on functional equivalence, long-term availability, and stable production quality. Each unit is manufactured and tested to ensure compatibility with Profibus-DP Class profiles and typical control platforms. This model does not require dimension or bore-size clarification, allowing direct selection based on electrical and communication requirements, which simplifies procurement and reduces project lead time.

Technical Data

| Parameter | Specification |

| Voltage supply | 10...30 VDC |

| Short-circuit proof | Yes |

| Consumption w/o load | ≤200 mA |

| Initializing time | ≤ 500 ms after power on |

| Interface | Profibus-DPV0/V2 |

| Function | Multiturn |

| Transmission rate | 9.6 ... 12000 kBaud |

| Device address | Rotary switches in bus connecting box |

| Steps per revolution | 8192 / 13 bit |

| Number of revolutions | 65536 / 16 bit |

| Additional outputs | Square-wave TTL/HTL, TTL/RS422 |

| Sensing method | Magnetic |

| Interference immunity | EN 61000-6-2 |

| Emitted interference | EN 61000-6-3 |

| Programmable parameters | Steps per revolution, Number of revolutions, Preset, scaling, rotating direction |

| Diagnostic function | Position or parameter error |

| Status indicator | DUO-LED (bus connecting box) 4 LEDs in device back side |

| Approval | CE, UL approval / E217823 |

| Parameter | Specification |

| Size (flange) | ø115 mm |

| Shaft type | ø11 mm solid shaft |

| Flange | EURO flange B10, Housing foot B3 |

| Protection EN 60529 | IP 66 / IP 67 |

| Operating speed | ≤6000 rpm |

| Range of switching speed | ns (off) = ±2...6000 rpm |

| Operating torque typ. | 10 Ncm |

| Rotor moment of inertia | 1 $kgcm^2$ |

| Admitted shaft load | ≤450 N axial, ≤650 N radial |

| Material | Housing: aluminium alloy; Shaft: stainless steel |

| Corrosion protection | IEC 60068-2-52 Salt mist for ambient conditions CX (C5-M) according to ISO 12944-2 |

| Operating temperature | -40...+85 °C |

| Relative humidity | 95 % non-condensing |

| Resistance | Vibration: IEC 60068-2-6 (30 g, 10-2000 Hz) Shock: IEC 60068-2-27 (400 g, 1 ms) |

| Weight approx. | 2.7 kg (depending on version) |

| Connection | Bus connecting box, Terminal box incremental |