We offer a customized replacement solution for the PMG10-SHD.1FP0.36000.A Profibus-DP absolute encoder, developed to meet the original unit’s electrical, communication, and performance requirements. This replacement encoder is engineered for seamless integration into existing fieldbus networks without modifications to PLC logic, motion control configurations, or Profibus settings, making it suitable for maintenance spares, retrofit upgrades, and long-term system support.

The PMG10-SHD series enables absolute multiturn position feedback over a Profibus-DP interface, delivering stable position information across both singleturn and extended multiturn ranges. Equipped for RS485-based Profibus communication, the encoder supports deterministic data exchange with industrial controllers, offering robust immunity to electrical noise and enhanced stability in harsh operating environments. Programmable features including preset values, scaling, and rotation direction allow the replacement to adapt easily to diverse control architectures while maintaining consistent feedback behavior.

Designed for industrial automation applications, the encoder’s communication and interface structure align with standard Profibus profile classes, ensuring compatibility with widely used PLC and motion platforms. Its dependable data integrity and configuration flexibility make this replacement a strong candidate for applications where precise absolute feedback is essential, including servo drives, packaging machinery, handling systems, and process automation.

This customized replacement solution delivers accurate absolute position feedback, Profibus-DP network compatibility, and long service life, providing dependable performance in continuous operation scenarios across industrial environments.

Technical Data

| Parameter | Specification |

| Voltage supply | 10...30 VDC |

| Short-circuit proof | Yes |

| Consumption w/o load | ≤200 mA |

| Initializing time | ≤ 500 ms after power on |

| Interface | Profibus-DPV0/V2 |

| Function | Multiturn |

| Transmission rate | 9.6 ... 12000 kBaud |

| Device address | Rotary switches in bus connecting box |

| Steps per revolution | 8192 / 13 bit |

| Number of revolutions | 65536 / 16 bit |

| Additional outputs | Square-wave TTL/HTL, TTL/RS422 |

| Sensing method | Magnetic |

| Interference immunity | EN 61000-6-2 |

| Emitted interference | EN 61000-6-3 |

| Programmable parameters | Steps per revolution, Number of revolutions, Preset, scaling, rotating direction |

| Diagnostic function | Position or parameter error |

| Status indicator | DUO-LED (bus connecting box) 4 LEDs in device back side |

| Approval | CE, UL approval / E217823 |

| Parameter | Specification |

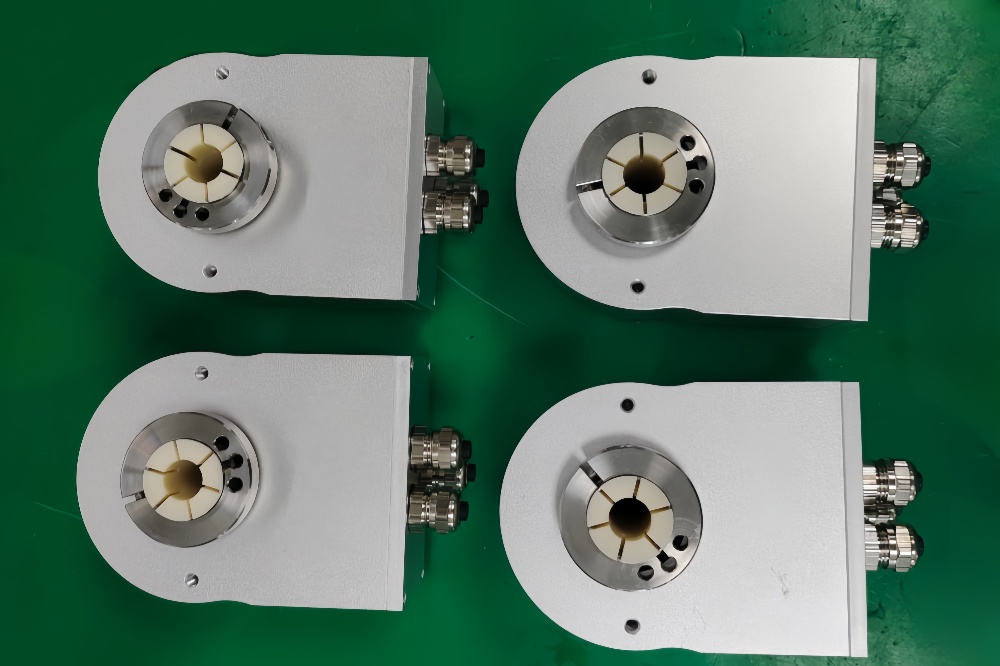

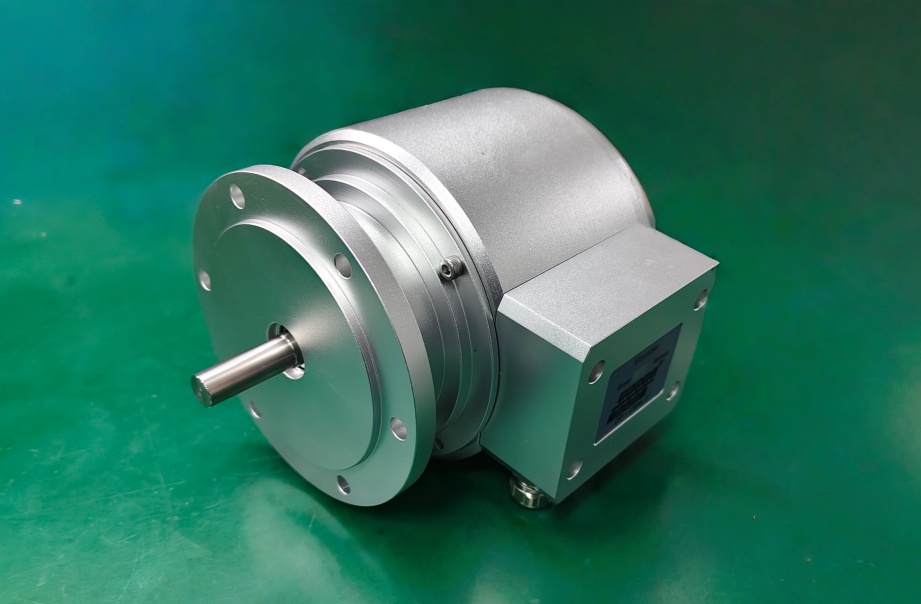

| Size (flange) | ø115 mm |

| Shaft type | ø11 mm solid shaft |

| Flange | EURO flange B10, Housing foot B3 |

| Protection EN 60529 | IP 66 / IP 67 |

| Operating speed | ≤6000 rpm |

| Range of switching speed | ns (off) = ±2...6000 rpm |

| Operating torque typ. | 10 Ncm |

| Rotor moment of inertia | 1 $kgcm^2$ |

| Admitted shaft load | ≤450 N axial, ≤650 N radial |

| Material | Housing: aluminium alloy; Shaft: stainless steel |

| Corrosion protection | IEC 60068-2-52 Salt mist for ambient conditions CX (C5-M) according to ISO 12944-2 |

| Operating temperature | -40...+85 °C |

| Relative humidity | 95 % non-condensing |

| Resistance | Vibration: IEC 60068-2-6 (30 g, 10-2000 Hz) Shock: IEC 60068-2-27 (400 g, 1 ms) |

| Weight approx. | 2.7 kg (depending on version) |

| Connection | Bus connecting box, Terminal box incremental |