We provide fully customizable replacement solutions for the OCD-DPC1B-1412-C12S-H72 absolute encoder. Our team can tailor specifications, performance parameters, and physical dimensions to ensure full compatibility with the original encoder or even exceed its performance, while guaranteeing seamless integration into your system. Customization covers resolution, mechanical size, and environmental protection ratings, among other aspects. As a trusted alternative supplier, we deliver dedicated technical support designed to meet your specific application needs.

Interface

Interface Profibus DP Profile DPV0, DPV1 and DPV2 Class 2 (EN50170 + EN50254) Diagnostics Memory Manual Functions Address selector switch 0-99 and terminal resistor (with connection cap) Features Round Axis Transmission Rate ≤12 Mbaud Interface Cycle Time ≥ 1 ms Programming Functions Resolution, gearing factor (physical resolution) , velocity scaling + filter, preset (zero point), counting direction, limit switches , node number, teach-in, diagnosis

Outputs

Output Driver Profibus Data Interface, galvanically isolated via opto-couplers

Electrical Data

Supply Voltage 10 – 30 VDC Current Consumption ≤ 115 mA @ 10 V DC, ≤ 50 mA @ 30 V DC Power Consumption ≤ 1.5 W Start-Up Time < 1 s Reverse Polarity Protection Yes Short Circuit Protection Yes EMC: Emitted Interference DIN EN 61000-6-4 EMC: Noise Immunity DIN EN 61000-6-2 MTTF 109 years @ 40 °C

Sensor

Technology Optical Resolution Singleturn 12 bit Resolution Multiturn 14 bit Multiturn Technology Mechanical Gearing (no Battery) Accuracy (INL) ±0.0220° (14 – 16 bit), ±0.0439° (≤13 bit) Code Binary

Environmental Specifications

Protection Class (Shaft) IP66/IP67 Protection Class (Housing) IP66/IP67 Storage Temperature -40 °C (-40 °F) – +85 °C (+185 °F) Humidity 98% RH, no condensation Max Temperature +85 °C (+185 °F) Min Temperature -40 °C (-40 °F)

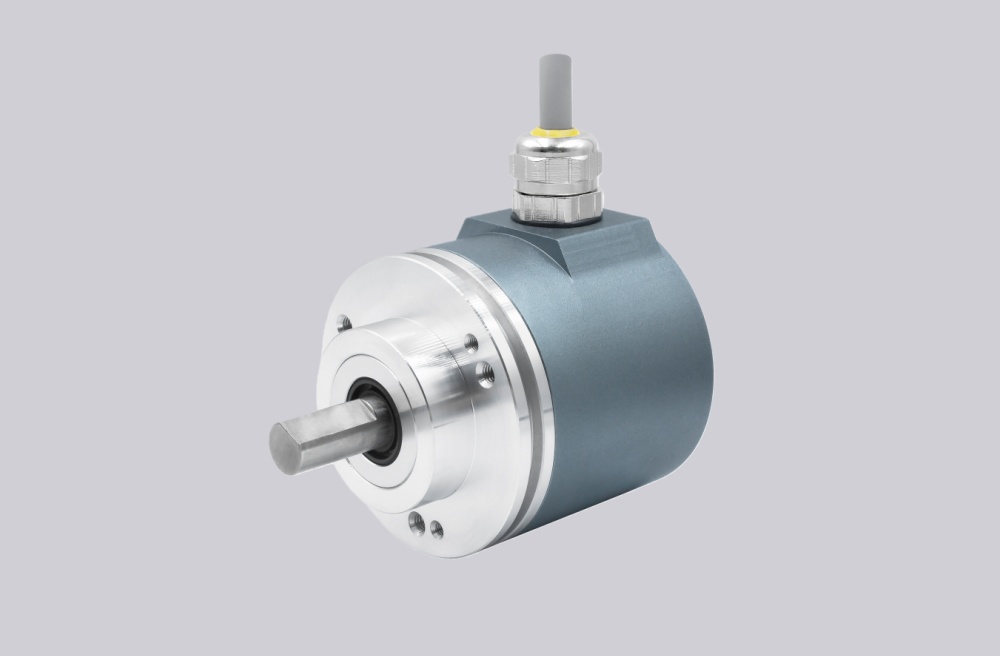

Mechanical Data

Connection Cap Material Aluminium Housing Material Steel Housing Coating Wet coating (RAL 9006 White Aluminium) + Cathodic corrosion protection (>720 h salt spay resistance) Flange Type Clamp, ø 58 mm (C) Flange Material Aluminum Shaft Type Solid, Single Flat, Length = 20 mm Shaft Diameter ø 12 mm (0.47") Shaft Material Stainless Steel V2A (1.4305, 303) Max. Shaft Load Axial 40 N, Radial 110 N Minimum Mechanical Lifetime(10^8 revolutions with Fa/Fr) 430 (20N/40N), 150 (40N/60N), 100 (40N/80N), 55 (40N/110N) Rotor Inertia ≤ 30 gcm² [≤ 0.17 oz-in²] Friction Torque ≤ 5 Ncm @ 20 °C, (7.1 oz-in @ 68 °F) Max. Permissible Mechanical Speed ≤ 3000 1/min Shock Resistance ≤ 100 g (half sine 6 ms, EN 60068-2-27) Permanent Shock Resistance ≤ 10 g (half sine 16 ms, EN 60068-2-29) Vibration Resistance ≤ 10 g (10 Hz – 1000 Hz, EN 60068-2-6) Length 80,5 mm (3.17") Weight 485 g (1.07 lb)

Electrical Connection

Connection Orientation Radial Connector 1 M12, Male, 4 pin, a coded Connection Cap Type Rotary switches with visible node number, No active components, Terminal resistor switch cut the outgoing bus too Connector 2 M12, Female, 5 pin, b coded Connector 3 M12, Male, 5 pin, b coded Connection Type 3 x M12 Connector (Profibus)

Certification

Product Life Cycle

Product Life Cycle Established