Engineering Context and Application Overview

Standard-housing SSI absolute encoders are among the most widely deployed rotary feedback devices in industrial automation, providing deterministic absolute position information with a simple synchronous serial interface. These encoders are built on high-precision magnetic sensing technology, supporting both single-turn and multi-turn configurations with high resolution and reliable shock and vibration tolerance.

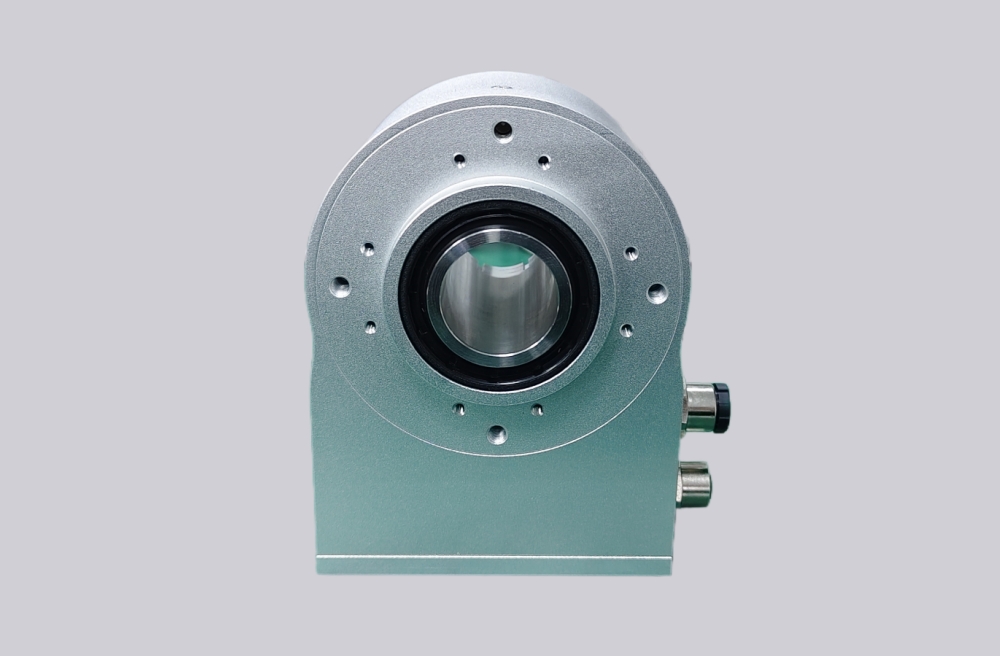

The 58mm standard form factor makes them mechanically compatible with a broad set of motion systems, offering a balanced trade-off between size, precision, and integration flexibility.

Key Functional Characteristics

SSI absolute encoders in the 58mm class typically offer:

- SSI interface with clock frequency support up to 2 MHz for high-speed communication

- Optional incremental signal output for hybrid control systems

- Single-turn resolution up to 21 bits for fine position detail

- Multi-turn count capability up to 14 bits for extended motion range

- Resistance to shock and vibration, and high environmental protection (up to IP68)

These performance characteristics make standard SSI absolute encoders suitable for both new machine designs and retrofit upgrades.

Mechanical Integration and Mounting Interfaces

Standard-housing SSI encoders are engineered for flexible mechanical installation:

- Clamp flange – facilitates secure and repeatable attachment to machine frames

- Blind hollow shaft flange – allows direct mounting to an existing shaft with minimal mechanical modifications

For each installation, engineers should evaluate shaft diameter, concentricity, and axial space to ensure proper mechanical interfacing and longevity.

Environmental Resilience and Reliability

Although standard models are not designed for hazardous or extreme conditions, they are rugged enough for typical industrial settings with:

- Operating temperatures covering common factory environments

- Resistance to shock and vibration inherent to automated systems

- High ingress protection ratings (IP65 or IP68 options) for dust and moisture tolerance

Appropriate grounding, shielding, and cable management further improve long-term reliability in electrically noisy installations.

Functional Behavior in Control Systems

SSI absolute encoders provide immediate position data upon power-up, eliminating the need for homing sequences. This property enhances machine startup behavior and reduces commissioning time. In real-world automation applications, mechanical integration quality — such as shaft alignment and mounting stiffness — often determines overall system performance more than interface resolution.

Typical Application Scenarios

Standard-housing SSI absolute encoders are broadly applied in:

- Packaging, assembly, and processing machinery

- Conveyor and material handling systems

- Machine axes requiring accurate position feedback

- Retrofit applications replacing legacy incremental or SSI devices

Their compact form factor and broad resolution range enable flexibility across many industrial implementations.

Engineering Selection Summary

Standard-housing SSI absolute encoders offer a reliable baseline solution for industrial position feedback. Their combination of mechanical adaptability, high resolution, and robust field performance makes them suitable for a wide variety of automated machinery. Proper evaluation of mechanical interfaces and installation conditions during selection ensures long-term system stability.

Engineering Reference

For detailed specifications and mechanical drawings, refer to the corresponding product documentation during final selection.

Reference:SSI Absolute Encoder SAS/M58