Hollow-Shaft SSI Absolute Encoders in Modern Automation Systems

Hollow-shaft SSI absolute encoders are specifically designed for applications where direct shaft mounting is preferred or required. Compared with solid-shaft designs, hollow-shaft encoders enable a more compact mechanical layout by allowing the machine shaft to pass directly through the encoder body.

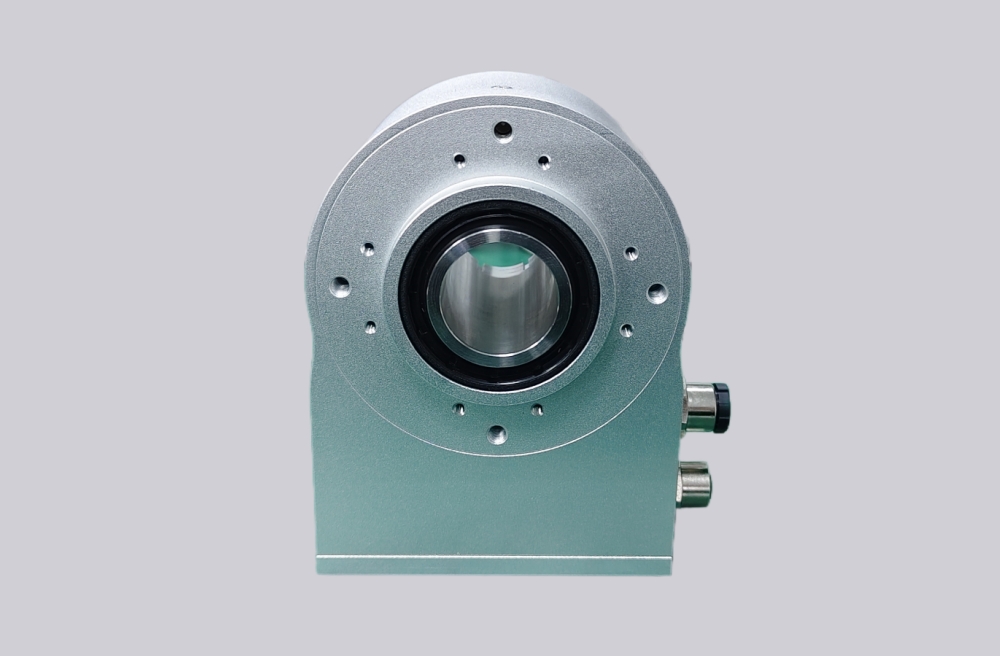

The SAS-M90 series hollow-shaft SSI absolute encoders provide deterministic absolute position feedback while simplifying mechanical integration, making them suitable for automation systems that prioritize installation efficiency and structural clarity.

Through-Shaft Mechanical Design Concept

The defining feature of the M90 series is its through hollow shaft design, which allows the encoder to be mounted concentrically around an existing machine shaft.

From a mechanical engineering perspective, this design offers several advantages:

- Elimination of intermediate shaft interfaces

- Reduced axial installation length

- Direct transfer of rotational position without additional mechanical elements

The encoder is typically secured using a clamping flange, ensuring stable torque transmission and reliable positioning under continuous operation.

Shaft Alignment and Installation Accuracy

While hollow-shaft encoders simplify mechanical layouts, they place higher demands on installation accuracy. Proper shaft alignment is critical to ensure long-term reliability.

Key installation considerations include:

- Controlled shaft concentricity and surface quality

- Uniform clamping force to avoid shaft deformation

- Precise axial positioning to prevent bearing preload

When these conditions are met, hollow-shaft SSI absolute encoders provide stable mechanical performance with minimal maintenance requirements.

SSI Absolute Position Feedback Characteristics

Functionally, the SAS-M90 series provides absolute position output via the SSI (Synchronous Serial Interface), ensuring deterministic and repeatable data transmission.

Typical functional characteristics include:

- Absolute position availability immediately after power-up

- High-resolution single-turn and multi-turn position encoding

- Synchronous, clock-driven data transmission

- Stable communication in electrically noisy industrial environments

The SSI interface is particularly suitable for motion control systems where reliable absolute position information is required during startup and fault recovery.

Environmental Suitability and Operating Conditions

Hollow-shaft SSI absolute encoders in the M90 series are intended for standard industrial environments, including:

- Indoor automation systems

- Controlled temperature ranges

- Moderate exposure to dust and moisture

They are not designed for hazardous or explosion-classified areas. For such environments, explosion-proof encoder designs should be selected instead.

Within their intended operating range, hollow-shaft encoders offer an effective balance between mechanical simplicity and operational stability.

Typical Application Scenarios

Hollow-shaft SSI absolute encoders are widely applied in:

- Servo drive systems and positioning axes

- Conveyor and material handling equipment

- Packaging machinery with compact mechanical layouts

- Rotary tables and indexing systems

Their through-shaft design allows them to integrate seamlessly into existing shaft structures, making them particularly suitable for both new machine designs and retrofit projects.

Retrofit and Replacement Considerations

In retrofit applications, hollow-shaft SSI absolute encoders are often selected when:

- Existing machine shafts must be retained

- Axial installation space is limited

- Simplified mechanical assembly is desired

When replacing an existing encoder, engineers should confirm shaft diameter compatibility and mounting interface details to ensure proper mechanical fit.

Engineering Selection Summary

The SAS-M90 hollow-shaft SSI absolute encoder series is designed for applications requiring direct shaft mounting and compact mechanical integration. Its through-shaft design, combined with deterministic SSI communication, enables reliable absolute position feedback while reducing mechanical complexity.

Careful attention to shaft alignment and mounting accuracy ensures long-term operational stability and consistent system performance.

Technical Reference

For detailed specifications and mechanical drawings, refer to the corresponding product documentation during final selection.

Reference:Hollow-Shaft SSI Absolute Encoder