We provide a 1:1 replacement solution for the AMG11P13Z0, specifically designed for systems using the Profibus-DP communication interface. This encoder is intended for applications that require stable and deterministic absolute position feedback, making it suitable for industrial automation, drive systems, and motion control applications where reliability and long-term availability are critical.

The replacement encoder follows the same optical sensing principle as the original design, ensuring accurate and repeatable position measurement. With Profibus-DP communication, it supports reliable cyclic data exchange and seamless integration into existing fieldbus networks without changes to PLC configuration or control logic. Its robust mechanical construction is well suited for continuous operation in industrial environments, maintaining performance under vibration, shock, and electrical interference.

As a Profibus 1:1 replacement, this solution is engineered to match the original encoder’s electrical behavior, interface characteristics, and functional performance. Mechanical and connection details are verified during the customization process to ensure direct installation. By choosing this replacement, users benefit from predictable lead times, stable long-term supply, and professional engineering support, while keeping system downtime and integration risk to a minimum.

Technical data

| Property | Value |

| Voltage supply | 9...30 VDC |

| Consumption w/o load | ≤100 mA (per interface SSI) ≤250 mA (per interface bus) |

| Initializing time | ≤200 ms after power on |

| Interface | SSI, Profibus-DPV0, CANopen®, DeviceNet, PROFINET |

| Function | Multiturn |

| Transmission rate | 9.6 ... 12000 kBaud (Profibus) 10 ... 1000 kBaud (CANopen®) 125 ... 500 kBaud (DeviceNet) 100 MBaud (PROFINET) |

| Profile conformity | Profibus-DPV0 CANopen® CiA DSP 406 V 3.0 Device Profile Encoder V 1.0 Encoder profile PNO 3.162 |

| Device address | Rotary switches in bus cover |

| Steps per revolution | 8192 / 13 bit |

| Number of revolutions | ≤65536 / 16 bit |

| Additional outputs | Square-wave TTL (RS422) Square-wave HTL |

| Sensing method | Optical |

| Code | Gray (version SSI) |

| Code sequence | CW default |

| Inputs | SSI clock (version SSI) |

| Interference immunity | EN 61000-6-2 |

| Emitted interference | EN 61000-6-3 |

| Programmable parameters | Depending on the selected absolute interface |

| Property | Value |

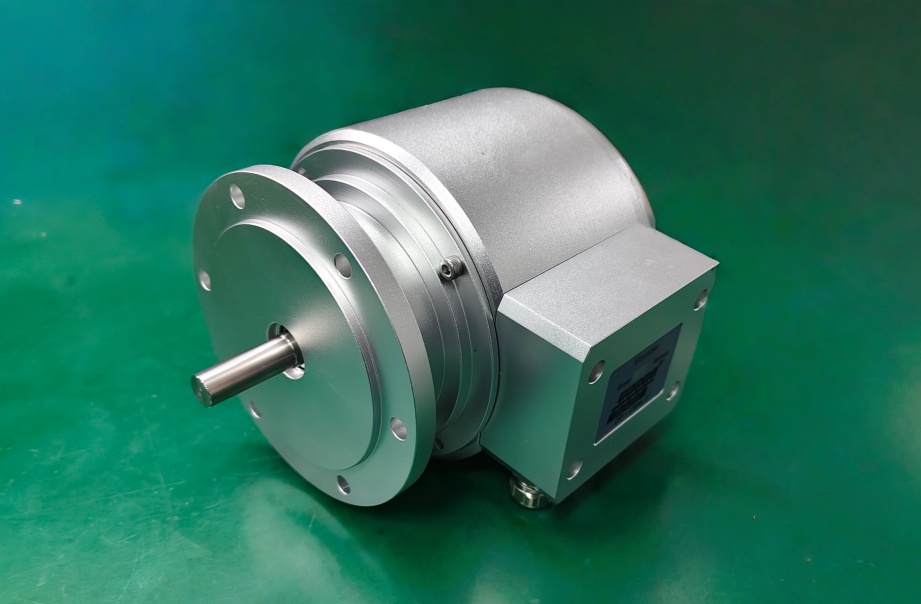

| Size (flange) | ø115 mm |

| Shaft type | ø11 mm solid shaft |

| Flange | EURO flange B10 |

| Protection EN 60529 | IP 67 |

| Operating speed | ≤3500 rpm (mechanical) |

| Operating torque typ. | 12 Ncm |

| Rotor moment of inertia | 780 gcm² |

| Admitted shaft load | ≤250 N axial, ≤350 N radial |

| Material | Housing: aluminium alloy Shaft: stainless steel |

| Corrosion protection | IEC 60068-2-52 Salt mist for ambient conditions CX (C5-M) according to ISO 12944-2 |

| Operating temperature | -20...+85 °C |

| Resistance | Vibration: IEC 60068-2-6 (10 g, 10-2000 Hz) Shock: IEC 60068-2-27 (100 g, 6 ms) |

| Explosion protection | II 3 G Ex ec IIC T4 Gc (gas) II 3 D Ex tc IIIC T135°C Dc (dust) (only with option ATEX) |

| Weight approx. | 3 kg (depending on version) |

| Connection | Bus cover Terminal box or flange connector M23, 12 pin (SSI/incremental) |