Engineering Background for Hollow-Shaft Applications

In many industrial automation systems, especially retrofit projects and compact machine designs, space constraints and mechanical simplicity are critical factors. Hollow-shaft absolute encoders address these challenges by allowing direct mounting onto the machine shaft, eliminating additional mechanical transmission components.

Hollow-shaft PROFIBUS DP absolute encoders combine this simplified mechanical interface with deterministic fieldbus communication, making them suitable for applications where installation efficiency and reliable position feedback are equally important.

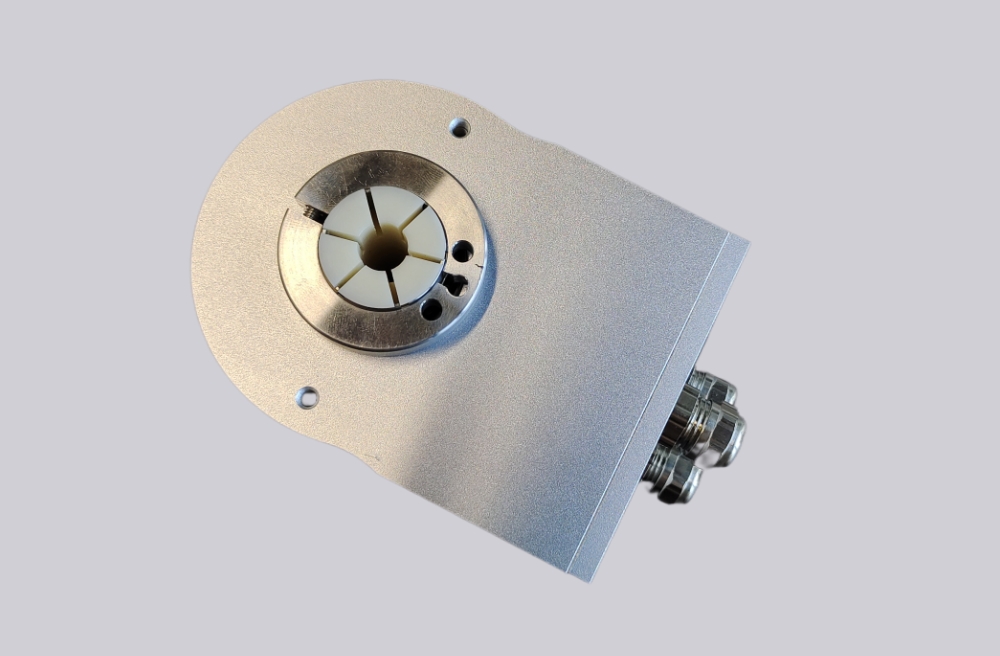

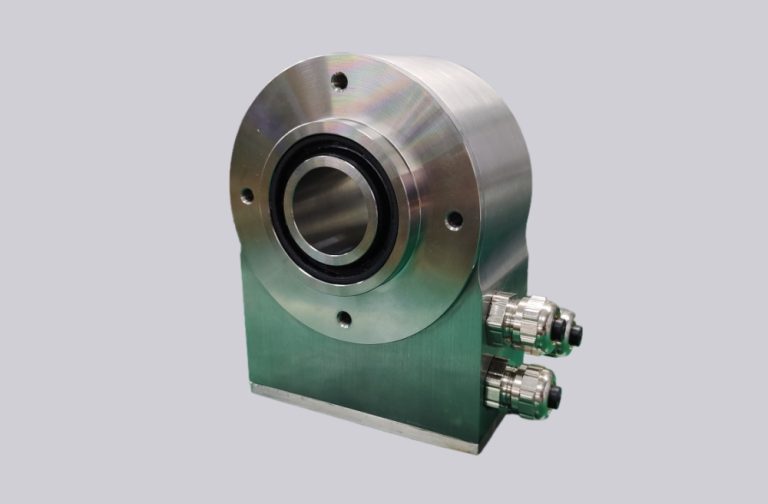

Hollow-Shaft Mechanical Design and Mounting Concept

The defining feature of hollow-shaft encoders is the through-bore shaft interface, which enables direct installation onto the driven shaft.

From an engineering perspective, this design offers:

- Reduced axial space requirements

- Simplified mechanical alignment

- Fewer mechanical interfaces compared to solid-shaft designs

Typical mounting configurations include:

- Clamp flange – providing secure axial fixation and controlled clamping force

- Blind hollow shaft flange – supporting compact integration where axial access is limited

During installation, shaft diameter tolerance, concentricity, and runout must be carefully evaluated to avoid excessive bearing load or long-term mechanical stress.

Absolute Position Feedback Characteristics

As with other absolute encoder designs, hollow-shaft PROFIBUS DP absolute encoders provide immediate position information after power-up. This characteristic is particularly valuable in machines where re-homing is impractical or where uncontrolled movement during restart must be avoided.

Absolute position feedback supports:

- Accurate synchronization of rotating axes

- Reliable recovery after power interruptions

- Improved operational safety and repeatability

Single-turn or multi-turn variants are selected based on the rotational travel required by the application.

PROFIBUS DP Communication and Network Integration

Hollow-shaft encoders integrate into PROFIBUS DP networks as standard slave devices, exchanging cyclic position data and diagnostic information with the master controller.

Key integration considerations include:

- Consistent PROFIBUS DP addressing and configuration

- Proper termination of the fieldbus segment

- Adequate shielding and grounding to maintain signal integrity

Because hollow-shaft encoders are often installed close to motors or rotating equipment, careful cable routing is essential to minimize electromagnetic interference.

Mechanical Alignment and Long-Term Reliability

While hollow-shaft designs simplify installation, they require precise mechanical alignment. Improper installation may introduce radial or axial forces that affect bearing life and measurement stability.

Engineers should ensure:

- Even clamping force distribution

- Secure fixation of anti-rotation elements

- Strain relief for PROFIBUS cables near rotating components

Correct mechanical practice directly contributes to reliable long-term operation and reduced maintenance intervals.

Typical Industrial Applications

Hollow-shaft PROFIBUS DP absolute encoders are commonly used in:

- Drive systems with limited installation space

- Conveyor rollers and rotating drums

- Retrofit upgrades replacing incremental encoders

- Compact automation equipment with direct shaft access

In these scenarios, the combination of direct mounting and deterministic communication simplifies both mechanical and control system integration.

Engineering Selection Summary

From an engineering selection standpoint, hollow-shaft PROFIBUS DP absolute encoders are suitable for applications requiring:

- Direct shaft mounting with reduced mechanical complexity

- Reliable absolute position feedback

- Deterministic PROFIBUS DP communication

- Flexible installation via clamp or blind hollow shaft flanges

Proper assessment of shaft geometry, alignment conditions, and network design is essential to achieving stable and long-lasting performance.

Engineering Reference

For detailed specifications and mechanical drawings, refer to the corresponding product documentation during final selection.