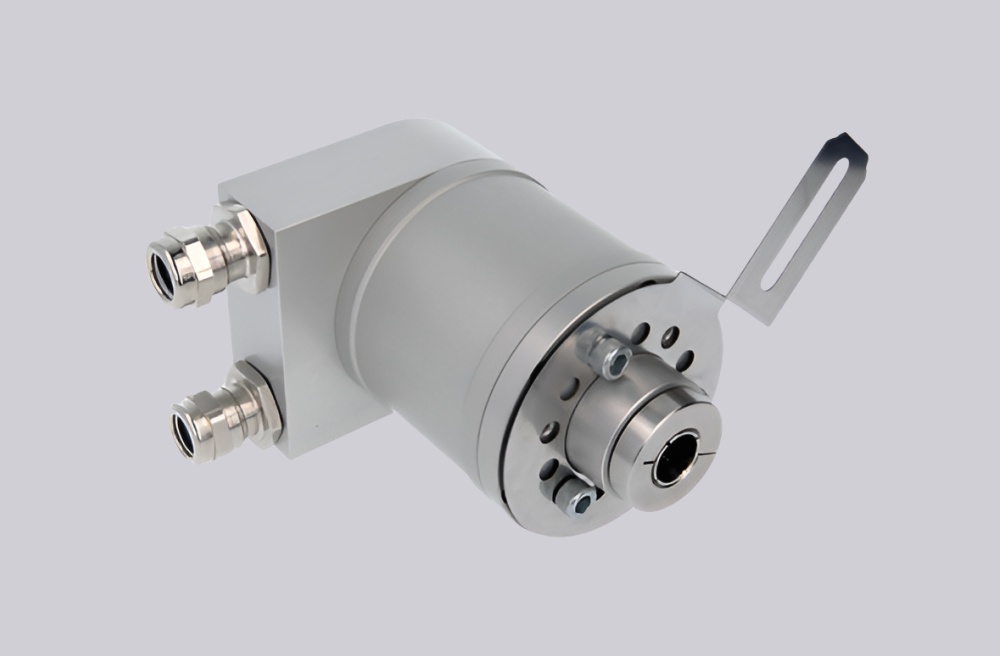

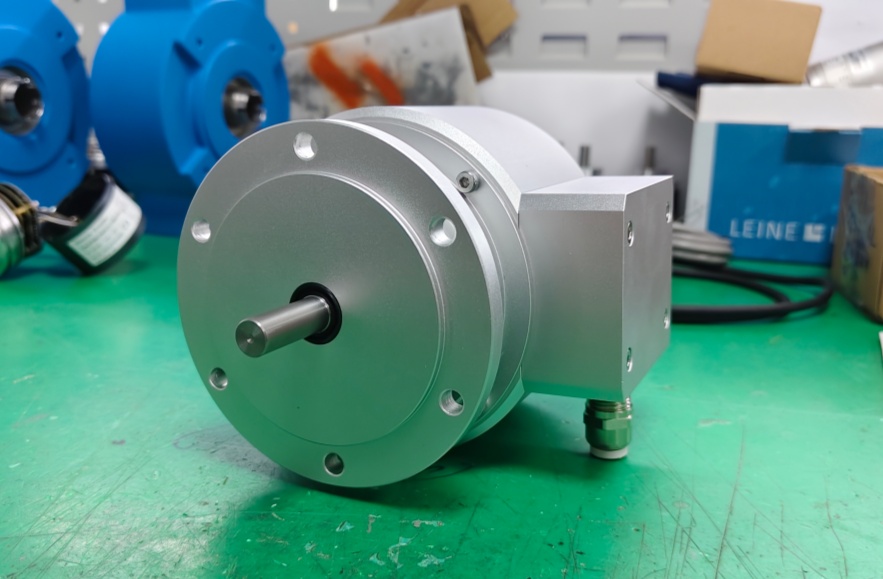

We can provide a customized replacement solution for the PMG10-SHD.12UG.20000.A absolute multiturn encoder with SSI interface. This replacement is engineered to align with the original unit’s electrical characteristics, SSI timing behavior, and communication protocol, enabling integration into existing motion control and automation systems without requiring modifications to PLC logic or fieldbus configuration.

The PMG10-SHD series offers absolute position feedback via a Synchronous Serial Interface (SSI), delivering stable multiturn position information suitable for high-performance applications such as servo axes, rotary tables, and handling machinery. With robust RS422/TTL driver options and deterministic data exchange, the replacement maintains consistent signal integrity even in electrically noisy industrial environments. Programmable encoder parameters—including preset values, scaling, and direction settings—allow the unit to be tailored to specific control requirements.

Designed for industrial use, this replacement solution emphasizes signal stability, repeatability, and long-term availability, supporting high shaft speeds and continuous operation. The structural design and interface logic are optimized to match typical OEM installations, minimizing integration risk. This customized encoder replacement provides dependable feedback performance where precise absolute positioning is required, such as automated production lines and motion control applications.

Technical Data

| Parameter | Specification |

| Voltage supply | 4.75...30 VDC |

| Short-circuit proof | Yes |

| Consumption w/o load | ≤100 mA (SSI) |

| Initializing time | ≤ 500 ms after power on |

| Interface | SSI |

| Function | Multiturn |

| Steps per revolution | 1048576 / 20 bit |

| Number of revolutions | 1048576 / 20 bit |

| Additional outputs | Square-wave TTL/HTL, TTL/RS422 |

| Sensing method | Magnetic |

| Code | Gray or binary |

| Code sequence | CW (factory setting) |

| Input signals | SSI clock, PRESET, rotating direction |

| Interference immunity | EN 61000-6-2 |

| Emitted interference | EN 61000-6-3 |

| Diagnostic function | Function control |

| Status indicator | 4 LEDs in device back side |

| Approval | CE, UL approval / E217823 |

| Parameter | Specification |

| Size (flange) | ø115 mm |

| Shaft type | ø11 mm solid shaft |

| Flange | EURO flange B10, Housing foot B3 |

| Protection EN 60529 | IP 66 / IP 67 |

| Operating speed | ≤12000 rpm |

| Range of switching speed | ns (off) = ±2...12000 rpm |

| Operating torque typ. | 10 Ncm |

| Rotor moment of inertia | 1 $kgcm^2$ |

| Admitted shaft load | ≤450 N axial, ≤650 N radial |

| Material | Housing: aluminium alloy; Shaft: stainless steel |

| Corrosion protection | IEC 60068-2-52 Salt mist for ambient conditions CX (C5-M) according to ISO 12944-2 |

| Operating temperature | -40...+95 °C |

| Relative humidity | 95 % non-condensing |

| Resistance | Vibration: IEC 60068-2-6 (30 g, 10-2000 Hz) Shock: IEC 60068-2-27 (400 g, 1 ms) |

| Weight approx. | 1.9 kg (depending on version) |

| Connection | Terminal box, Flange connector M23 |