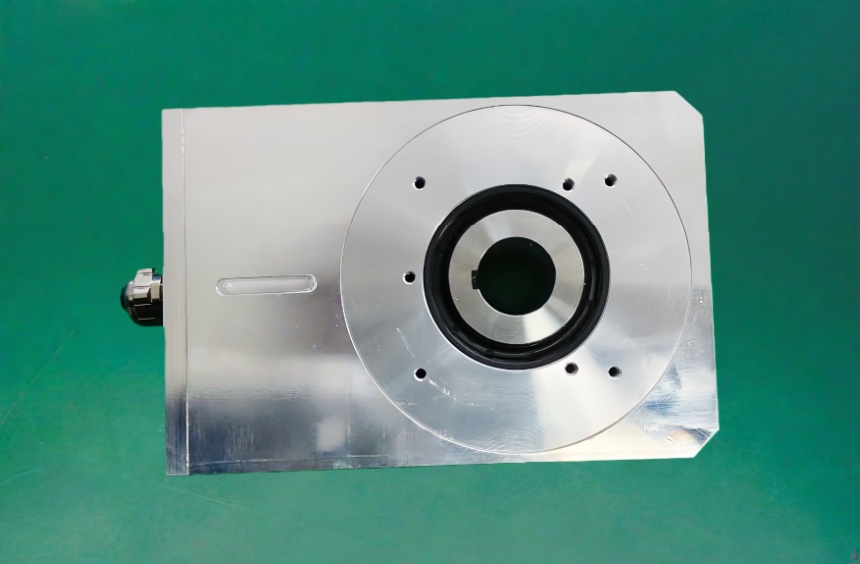

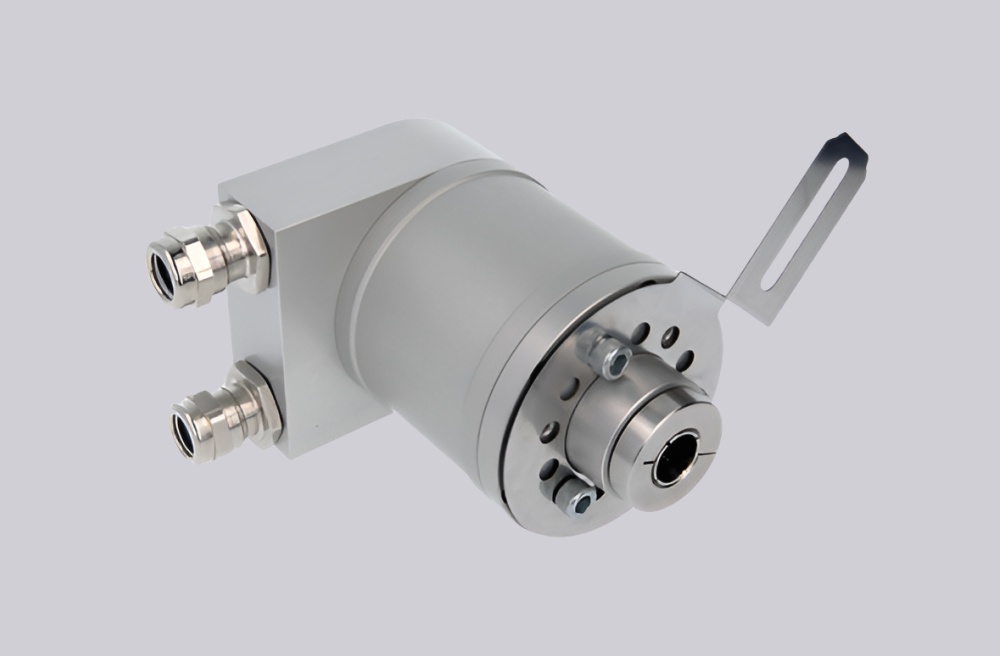

We provide a precise SSI multiturn absolute encoder 1:1 replacement solution for the X 700.M141202 and X 700.M141402 models, engineered for seamless integration into existing industrial automation and motion control systems. This replacement maintains the original encoders’ electrical interface, SSI communication behavior, resolution, and mechanical dimensions, enabling direct installation without modifications to PLC configuration, drive parameters, or wiring layouts.

These encoders deliver high-resolution absolute position feedback via a Synchronous Serial Interface (SSI), combining 14-bit singleturn accuracy with 12-bit multiturn tracking to provide a complete absolute position value across multiple revolutions. Support for Gray or binary code formats ensures consistent and repeatable data transmission even in environments with rapid speed changes or continuous motion. Fast initialization and robust signal integrity make this solution suitable for real-time feedback in servo drives, CNC machines, robotic axes, and precision positioning systems.

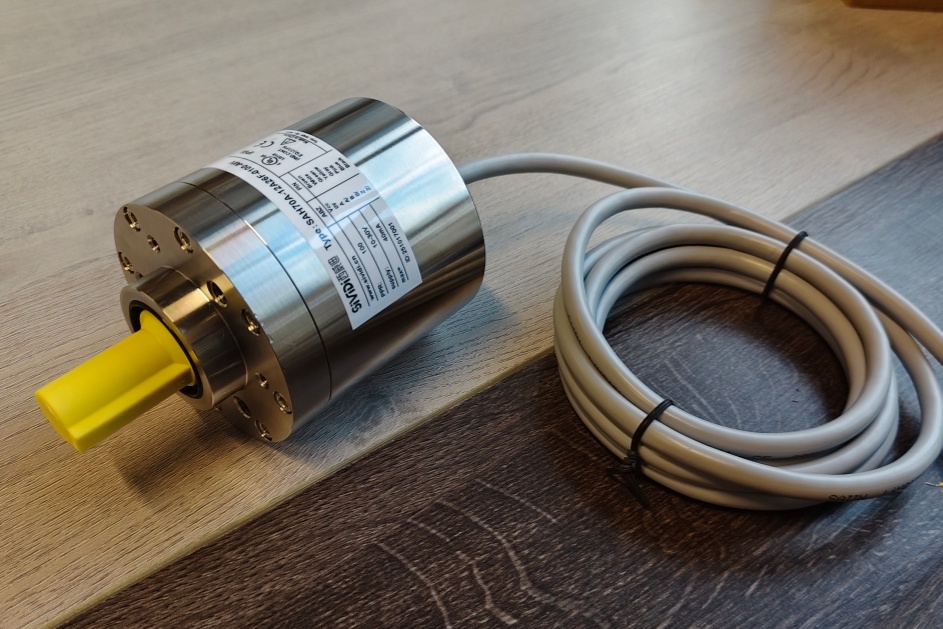

Mechanically, the replacement units align with common industrial shaft and flange mounting standards, allowing straightforward substitution without mechanical redesign. Their industrial-grade housing with IP67 protection and robust optical sensing design deliver reliable performance in harsh conditions subject to vibration, shock, dust, and moisture. Integrated self-diagnostic functions continuously monitor code stability and internal signal integrity, helping to detect anomalies before they impact system operation.

This 1:1 replacement solution is ideal for high-performance automated equipment, motion control applications, and positioning systems that demand accurate absolute feedback and dependable long-term operation.

Technical data

| Parameter | Value |

| Voltage supply | 10...30 VDC |

| Reverse polarity protection | Yes |

| Consumption w/o load | ≤50 mA (24 VDC) |

| Initializing time typ. | 20 ms after power on |

| Interface | SSI |

| Function | Multiturn |

| Steps per revolution | 16384 / 14 bit |

| Number of revolutions | 4096 / 12 bit |

| Absolute accuracy | ±0.025 ° |

| Sensing method | Optical |

| Code | Gray or binary |

| Code sequence | CW/CCW coded by connection |

| Inputs | SSI clock, Control signals UP/DOWN inv. and zero |

| Output stages | SSI data: Linedriver RS422, Diagnostic outputs push-pull |

| Interference immunity | DIN EN 61000-6-2 |

| Emitted interference | DIN EN 61000-6-4 |

| Diagnostic functions | Self-diagnosis, Multiturn sensing |

| Parameter | Value |

| Size (flange) | ø70 mm |

| Shaft type | ø10 mm solid shaft (clamping flange) |

| Flange | Clamping flange |

| Protection DIN EN 60529 | IP 67 |

| Operating speed | ≤6000 rpm (mechanical), ≤6000 rpm (electric) |

| Starting acceleration | ≤1000 U/s² |

| Starting torque | ≤0.4 Nm (+25 °C) |

| Admitted shaft load | ≤60 N axial, ≤50 N radial |

| Materials | Housing: stainless steel, Flange: stainless steel |

| Operating temperature | -20...+70 °C |

| Relative humidity | 95 % non-condensing |

| Resistance | DIN EN 60068-2-6 (Vibration ±0.75 mm - 10-58 Hz, 10 g - 58-2000 Hz) DIN EN 60068-2-27 (Shock 200 g, 6 ms) |

| Explosion protection | Ex II 2G Ex d IIC T6, Ex II 2D |

| Weight approx. | 1300 g |