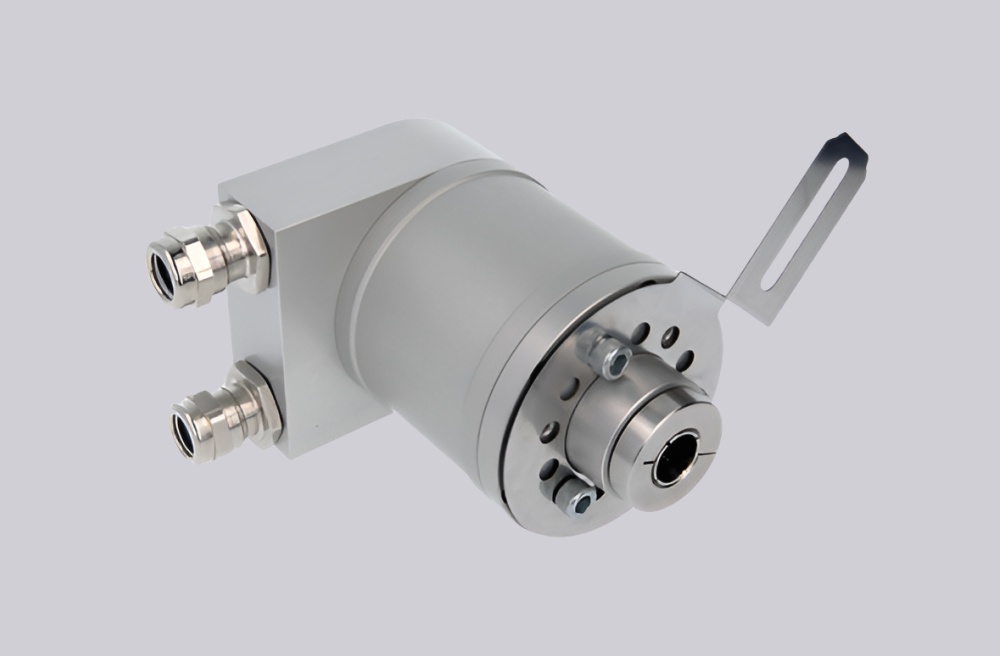

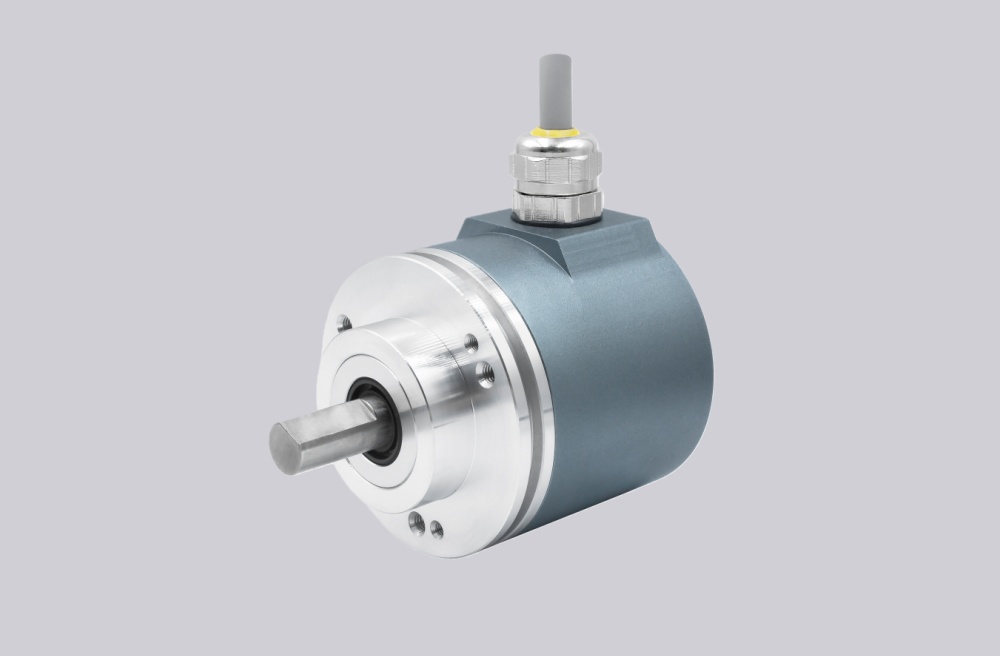

We provide a dependable SSI encoder 1:1 replacement solution for the GM400.0101102 and GM400.A101102 models, designed to ensure direct compatibility with existing absolute multiturn encoder installations. This replacement maintains the same interface logic and signal behavior, allowing it to be integrated without changes to control software or system configuration.

The encoder uses a Synchronous Serial Interface (SSI) to deliver absolute position data with high resolution across both singleturn and multiturn ranges. Stable data transmission and consistent timing characteristics support accurate position feedback even in applications with rapid motion or frequent sampling. Support for standard code formats ensures compatibility with a wide range of industrial controllers and motion systems.

From a mechanical standpoint, the replacement encoder is engineered to fit common mounting standards, enabling straightforward installation on existing shafts and flanges. The internal design incorporates continuous self-diagnostic monitoring, including checks of code stability, signal frequency limits, and internal electronic status. These features enhance operational reliability and help reduce the risk of unexpected failures.

This 1:1 replacement encoder is suitable for servo drives, automated production equipment, and industrial positioning systems where precise absolute feedback and long-term stability are essential.

Technical data

| Parameter | Value |

| Supply voltage | 10...30 VDC with reverse voltage protection |

| Current consumption | Max. 50 mA (w/o load) for 24 VDC |

| SSI pulse frequency | 62.5 kHz up to 1.5 MHz |

| Mono-flop time | 20 μs |

| Pulse space | Min. 25 μs |

| Code switching speed for sampling | 800 kHz |

| Deviation of sampling measuring step | 0.025 degree at 400 kHz 0.05 degree at 800 kHz |

| Electric connector | The electric connector must not be plugged on or removed whilst under voltage. |

| Parameter | Value |

| RPM value | mechanical: Max. 10,000 RPM electrical: Max. 6,000 RPM |

| Anlauf-Drehmoment | w/o seal (IP54): < 0.010 Nm with seal (IP65): < 0.015 Nm |

| Shaft loading | axial: < 20 N radial: < 40 N |

| Inertia torque | 2 x 10⁻⁶ kgm² |

| Material | Housing: Steel Flange: Aluminium |

| Weight | Approximately 400 g |

| Parameter | Value |

| Ambient temperature | -20...+60 °C |

| Storage temperature | -20...+70 °C |

| Protection to | Shaft w/o seal: IP 54 Shaft with seal: IP 65 |

| Relative humidity | Max. 95 %, non-condensing |

| Endurance - Vibration | IEC 68 Section 2 - 6 (≤100 m/s² / 16-2000 Hz) |

| Endurance - Shock | IEC 68 Section 2 - 27 (≤2000 m/s² / 6 ms) |

| Interference immunity | EN 50082-2 EN 61000-4 - 2 to 4 Severity grade 3 |

| Emmited interference | EN 50081-2 |