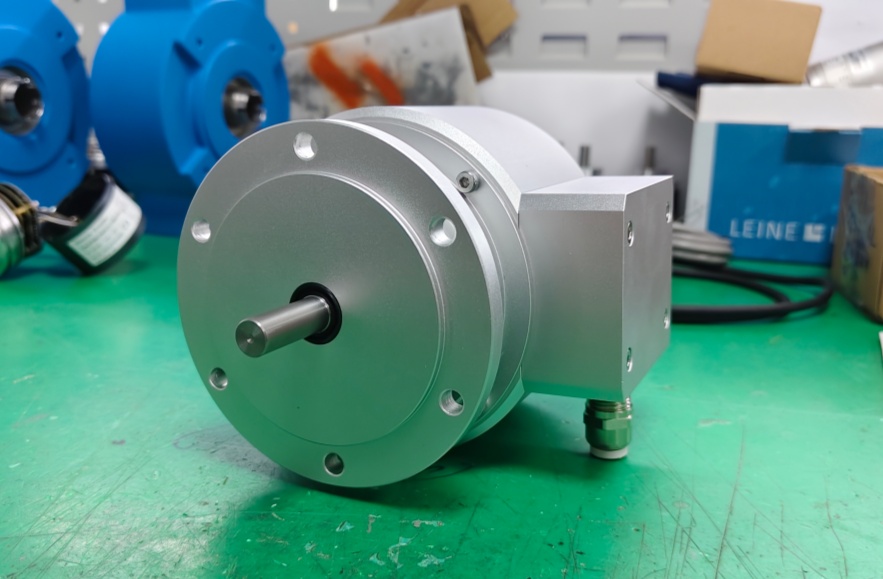

We provide a 1:1 replacement solution for the AMG81S25Z0 absolute encoder, engineered to match the original unit’s electrical interface, signal behavior, and mechanical mounting. This replacement fits directly into existing automation systems without requiring changes to PLC logic, fieldbus settings, or motion control parameters, making it suitable for maintenance replacements, retrofits, and equipment upgrades.

The AMG81S25Z0 encoder delivers optical absolute position feedback with high resolution and stable performance. It operates on a 10–30 V DC supply with reverse polarity protection, and supports programmable features such as CW/CCW code sequencing and selectable rotational direction to align with your existing control architecture. The integrated DUO‑LED status indicator and built‑in diagnostic functions provide clear visual feedback on operating status and error conditions, enhancing system dependability.

Mechanically, this replacement preserves the original flange and shaft interface dimensions, ensuring dimensional compatibility with existing mounts and couplings. The encoder’s design complies with industrial interference immunity and emission standards, offering stable communication even in electrically noisy environments.

This 1:1 replacement option delivers dependable absolute feedback performance, reliable diagnostics, and simplified integration for systems that require accurate position sensing with minimal configuration changes.

Technical Data

| Parameter | Value |

| Voltage supply | 9...30 VDC |

| Consumption w/o load | ≤100 mA (per interface SSI) ≤ 250 mA (per interface bus) |

| Initializing time | ≤ 200 ms after power on |

| Interface | SSI, Profibus-DPV0, CANopen® |

| Function | Multiturn |

| Transmission rate | 9.6 ... 12000 kBaud (Profibus) 10 ... 1000 kBaud (CANopen®) |

| Profile conformity | Profibus-DPV0 CANopen® CiA DSP 406 V 3.0 |

| Device address | Rotary switches in bus cover |

| Steps per revolution | 8192 / 13 bit |

| Number of revolutions | 4096 / 12 bit 65536 / 16 bit |

| Additional outputs | Square-wave TTL (RS422) Square-wave HTL |

| Sensing method | Optical |

| Code | Gray (version SSI) |

| Code sequence | CW default |

| Inputs | SSI clock (version SSI) |

| Incremental output | 2048 pulses per revolution |

| Interference immunity | EN 61000-6-2 |

| Emitted interference | EN 61000-6-3 |

| Programmable parameters | Depending on the selected absolute interface |

| Parameter | Value |

| Size (flange) | ø115 mm |

| Shaft type | ø11 mm solid shaft |

| Flange | EURO flange B10 |

| Protection EN 60529 | IP 55 |

| Operating speed | ≤ 3500 rpm (mechanical) |

| Operating torque | ≤ 10 Ncm |

| Rotor moment of inertia | 1.4 kgcm² |

| Admitted shaft load | ≤ 50 N axial ≤ 60 N radial |

| Material | Housing: aluminium alloy Shaft: stainless steel |

| Operating temperature | -20...+85 °C |

| Resistance | IEC 60068-2-6: Vibration 10 g, 10-2000 Hz IEC 60068-2-27: Shock 100 g, 6 ms |

| Explosion protection | II 3 G Ex ec IIC T4 Gc (gas) II 3 D Ex tc IIIB T120°C Dc (dust) (only with option ATEX) |

| Weight approx. | 1.7 kg (depending on version) |

| Connection | Bus cover Flange connector M23, 12-pin (SSI/incremental) |