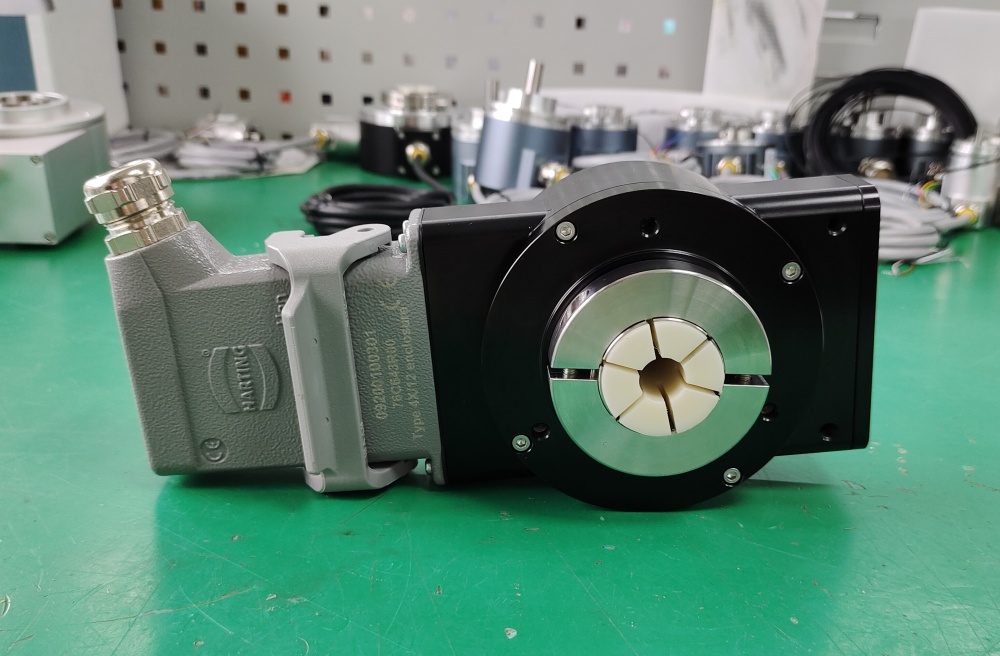

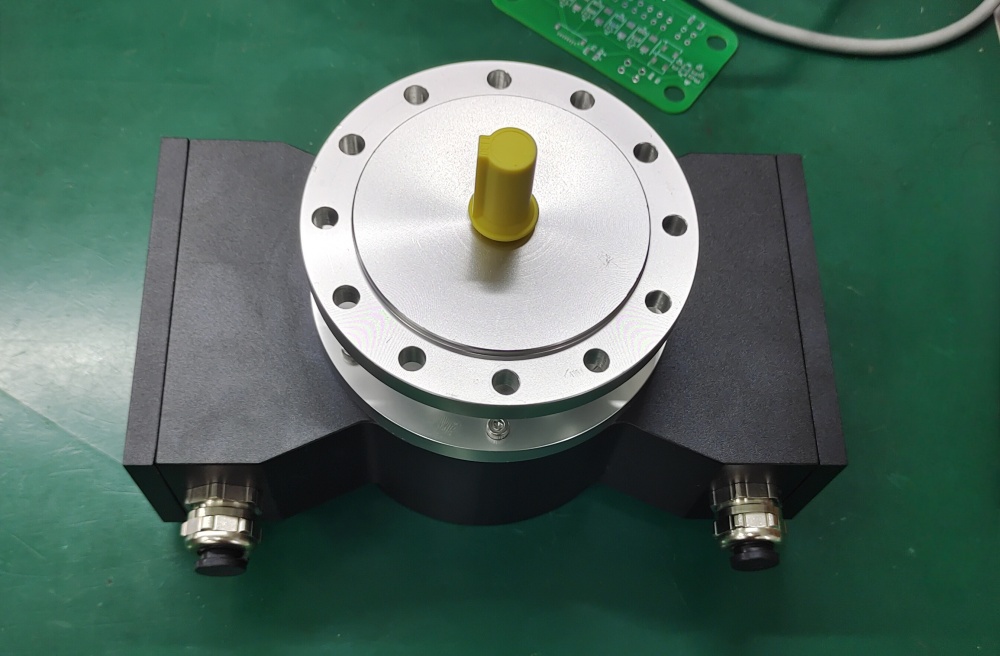

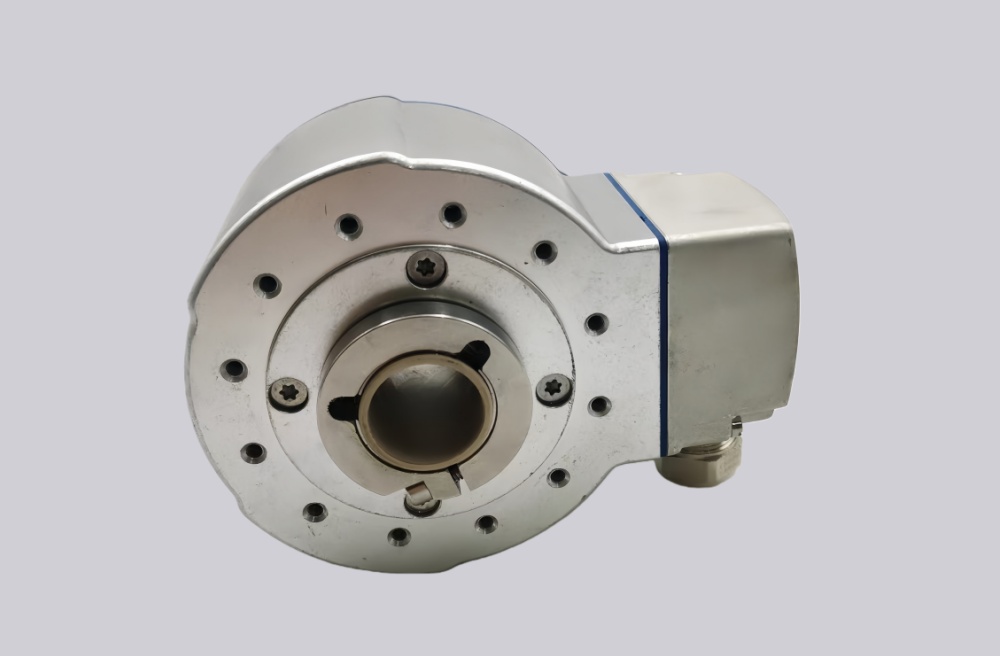

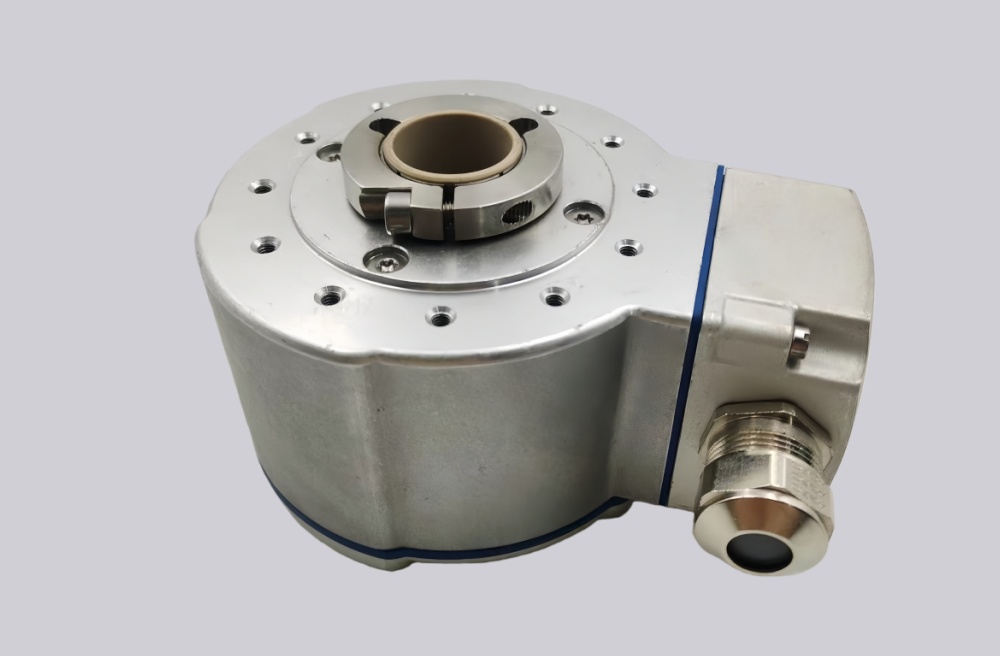

We can provide a customized incremental encoder replacement solution compatible with the specified model, without directly referencing the original brand. The replacement is engineered based on the customer’s actual installation conditions, including hollow shaft size, torque arm configuration, connector orientation, and environmental requirements. This ensures mechanical interchangeability and electrical compatibility rather than a one-size-fits-all substitution.

From a technical perspective, the original unit is a heavy-duty hollow shaft incremental encoder designed for high mechanical loads and harsh industrial environments. It operates with a 2048 PPR resolution, supports High-Current HTL (HCHTL) output, and works within a 9–30 VDC supply range. The encoder is typically used at high rotational speeds and requires strong resistance to vibration, shock, and shaft movement. Our replacement solution matches these core parameters, including pulse count, signal levels, and channel configuration, while maintaining IP67 protection and comparable axial and radial load capacity. Where required, output characteristics and cable or connector options can be fine-tuned to suit specific control systems.

In summary, this customized replacement encoder delivers reliable signal performance and mechanical robustness, making it suitable for heavy-duty drives, winches, conveyors, and rotating machinery where stable incremental feedback and long-term operational reliability are critical.

Technical data

| Parameter | Value |

| Operating temperature | -20 °C...+85 °C |

| Ingress protection class [IEC 60529] | IP67 (IP66 at shaft inlet) |

| Vibration [IEC 60068-2-64] | ≤ 20 g, 55-2000 Hz |

| Shock [IEC 60068-2-27] | ≤ 400 g, 3.5 ms |

| Shaft load max (axial/radial) | 50 N / 100 N |

| Rotational speed max | 6000 rpm |

| Shaft material | Stainless steel with insulated peek insert |

| Cover material | Aluminium (anodized) |

| Weight | 1400 g |

| Parameter | Value |

| Type | XHI |

| Model | 803 Standard |

| Shaft type | Ø25 mm through-going hollow shaft |

| Flange type | 87-flange |

| Resolution | 2048 ppr |

| Power supply | 9-30 Vdc |

| Output signal | High Current HTL (HCHTL) |

| Connection type | Cable gland |

| Connecting direction | Adjustable |

| Number of channels | 6 (S00, S00, S90, S90, Sref, Sref) |

| Torque support | 120° torque bracket |

| Overvoltage protection | With overvoltage protection |

| Cable gland dimension | M20 for Ø8-11 mm cables |

| Parameter | Value |

| Polarity protected | Yes |

| Short circuit protected incremental outputs | Yes |

| Current consumption (No load) | 60 mA at 24 Vdc (Max. 80 mA) |

| Incremental output load (max) | ± 40 mA |

| Output frequency max | 200 kHz |

| Cable length max | 350 m at 100 kHz |

| Channel separation | 90 °el ± 25 °el |

| Dividing error | ± 50 °el |