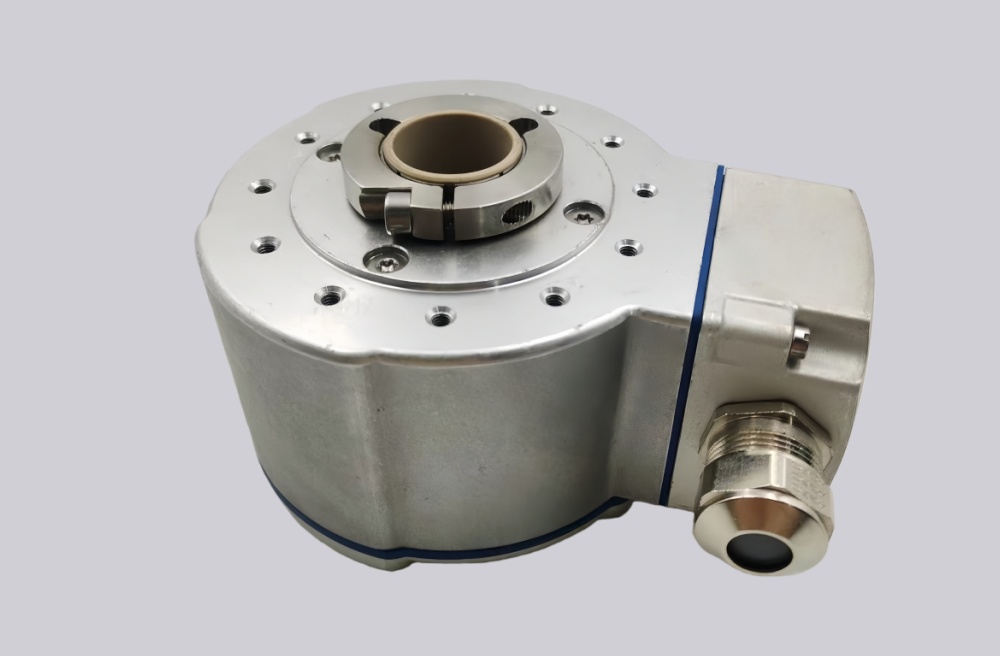

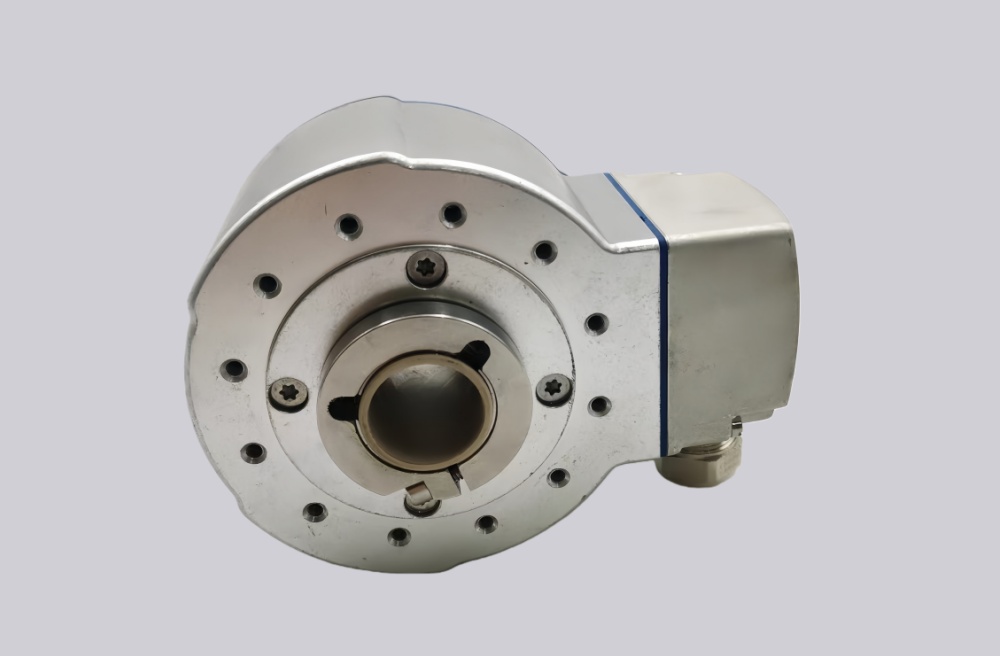

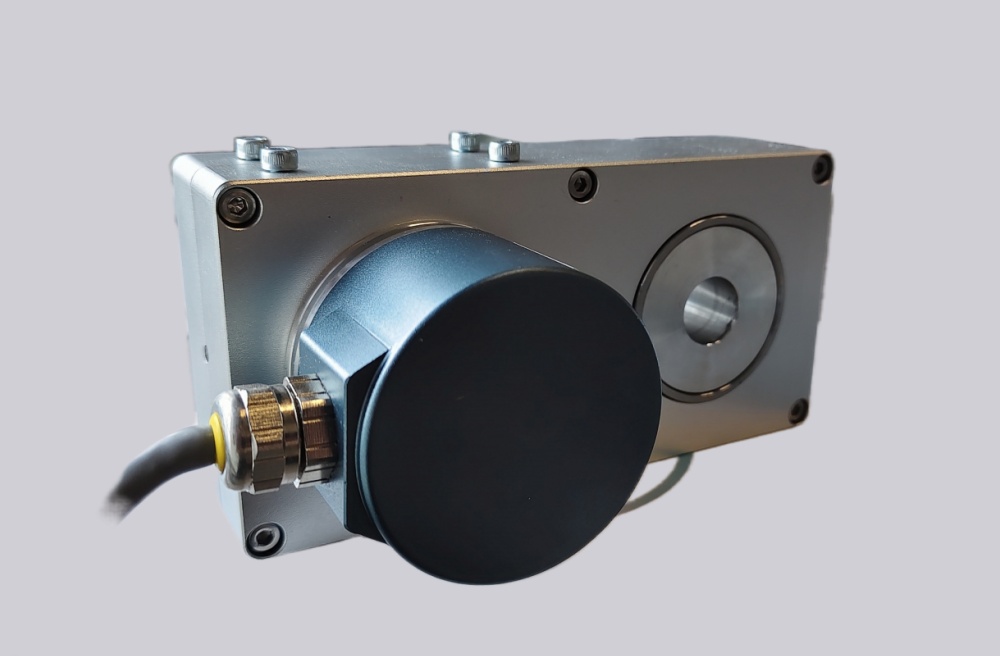

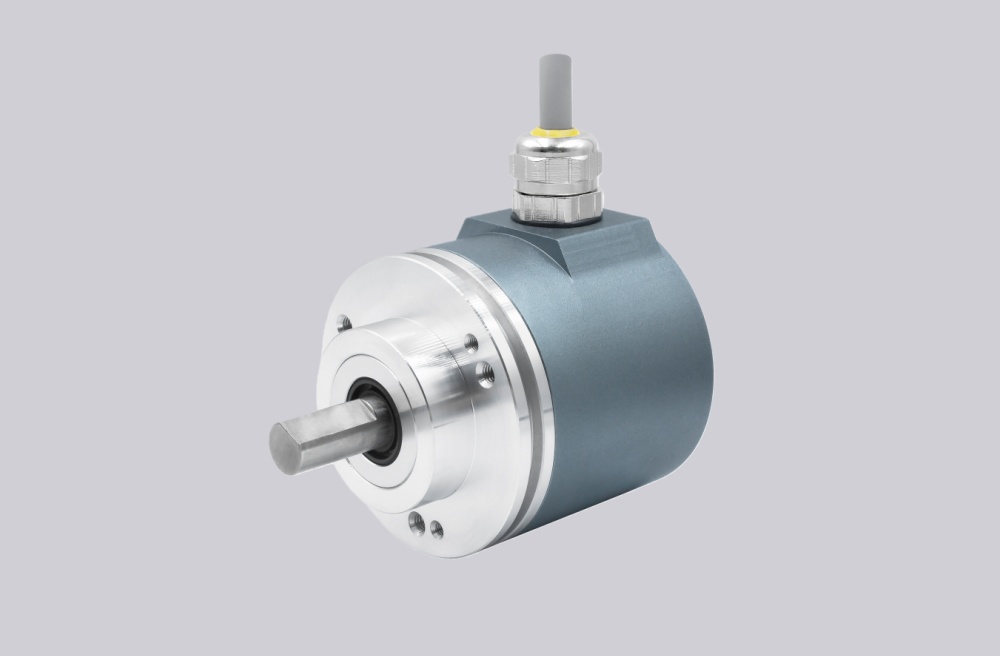

We can provide a fully customized replacement solution for this SSI-based absolute encoder combined with a 3-meter industrial-grade draw-wire mechanism, specifically engineered for lifting and positioning systems used in shuttle cars, stacker cranes, and trolley elevation applications. The replacement is not a generic substitution but a configuration tailored to the actual mechanical installation, travel length, mounting interface, and control system requirements. Encoder body, shaft interface, signal format, and draw-wire housing are coordinated as a single system to ensure accurate linear position feedback over the full stroke range.

From a technical perspective, the original configuration integrates a multi-turn absolute encoder with a 1:1 draw-wire transmission, converting linear motion into precise angular measurement without loss of position after power-off. The encoder operates using SSI Gray code communication, which is widely adopted in industrial automation due to its strong noise immunity and deterministic data transmission. With a resolution of 4096 steps per revolution and 4096 multi-turn counts, the system delivers high positioning accuracy across the entire 0–3000 mm effective measuring range. The electrical design supports a DC 10–32 V supply, enabling stable operation in mobile equipment and crane environments where voltage fluctuation is common. Mechanical robustness is ensured through high resistance to shock (up to 100 g) and vibration (20 g), making the solution suitable for frequent acceleration, deceleration, and vertical motion. Our customized replacement matches the original signal timing, maximum output frequency, and mechanical performance, while allowing adaptation of connector type, cable length, and housing orientation to simplify on-site installation.

In summary, this customized SSI draw-wire encoder replacement provides reliable absolute position feedback for vertical and horizontal motion systems. It is well suited for shuttle cars, lifting trolleys, automated storage systems, and similar material-handling equipment where precise positioning, repeatability, and resistance to harsh industrial conditions are critical.

Key Technical Parameters

- Encoder type: Absolute encoder, multi-turn

- Measurement principle: Draw-wire mechanism, 1:1 ratio

- Effective measuring length: 0–3000 mm

- Shaft diameter: 10 mm

- Resolution: 4096 × 4096

- Communication interface: SSI (Gray code)

- Supply voltage: DC 10–32 V

- Maximum output frequency: 300 kHz

- Maximum mechanical speed: 8000 rpm

- Shock resistance: 100 g

- Vibration resistance: 20 g

- Protection class: IP67

- Operating temperature: –20 °C to +85 °C

- Electrical connection: Industrial circular connector

- Mounting method: Housing-mounted fixing holes, integrated with draw-wire mechanical housing