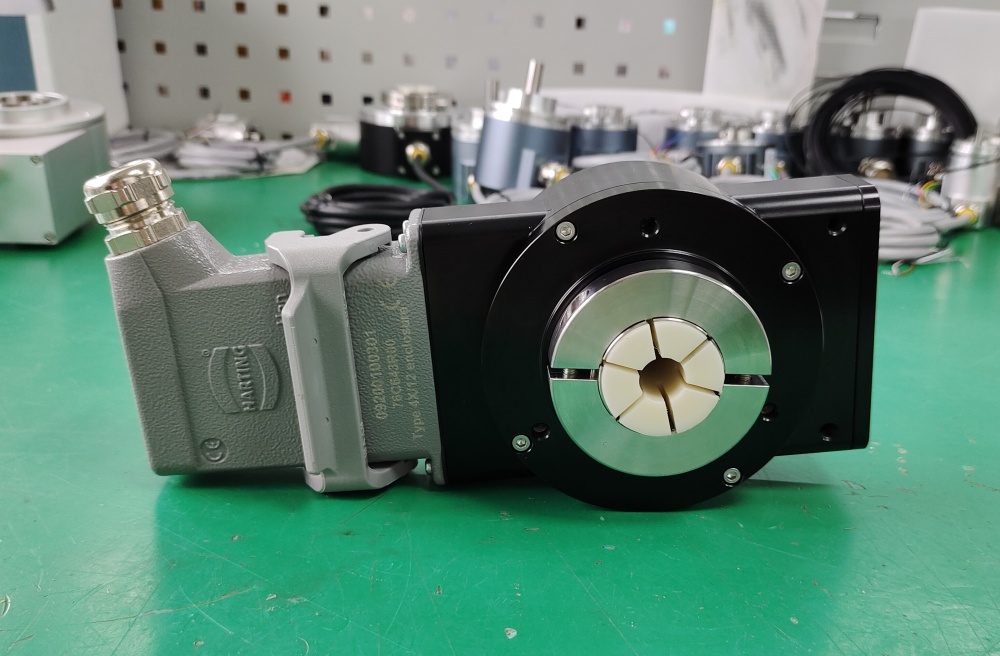

Recently, an early-generation encoder was encountered with an internal control board dated 2003, which means the product has now been in service for more than 20 years. From an engineering perspective, this highlights not only the durability of the original design but also the long lifecycle typical of industrial automation equipment.

Despite its age, this encoder is still required in certain applications, mainly for system maintenance, spare-part replacement, or legacy equipment support. The primary challenge is not technical feasibility, but rather limited availability through standard procurement channels, which makes sourcing increasingly difficult.

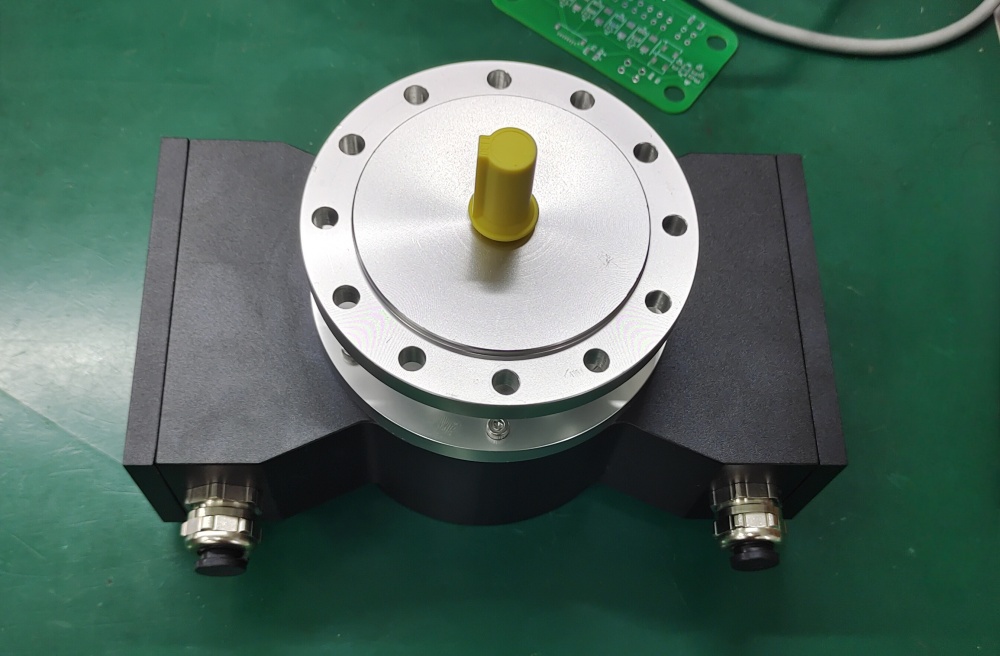

For cases like this, customized manufacturing based on the original specifications is a practical solution. Even though the original unit was an imported product, its functional structure, electrical interface, and signal logic can be analyzed and replicated to achieve a technically equivalent replacement. This allows existing systems to continue operating without modification.

Such requirements are typically highly specialized and niche, usually coming from users who operate long-running systems and prefer to maintain the original configuration rather than redesign the control architecture. While demand volume is low, the technical need is very real.

Users who encounter similar legacy encoder requirements are generally advised to seek specialized service providers capable of reverse engineering and custom production. Relevant contact information and technical references can usually be found through professional industrial directories and technical resource platforms.

This message is shared primarily as a technical information notice, with the hope that it may help users facing similar challenges with long-service encoder models. Opportunities to document and share legacy product information like this are becoming less frequent, but they remain valuable for maintaining continuity in industrial systems.