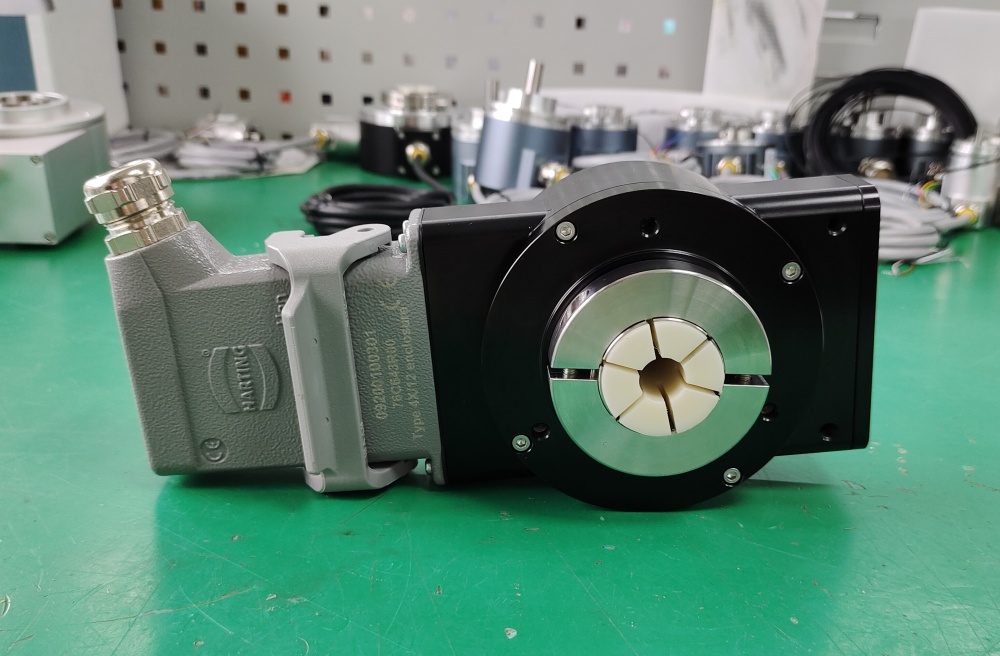

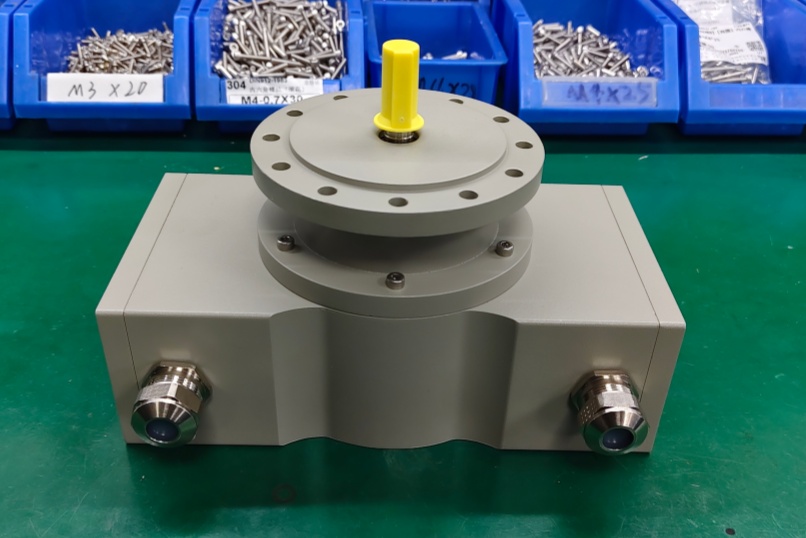

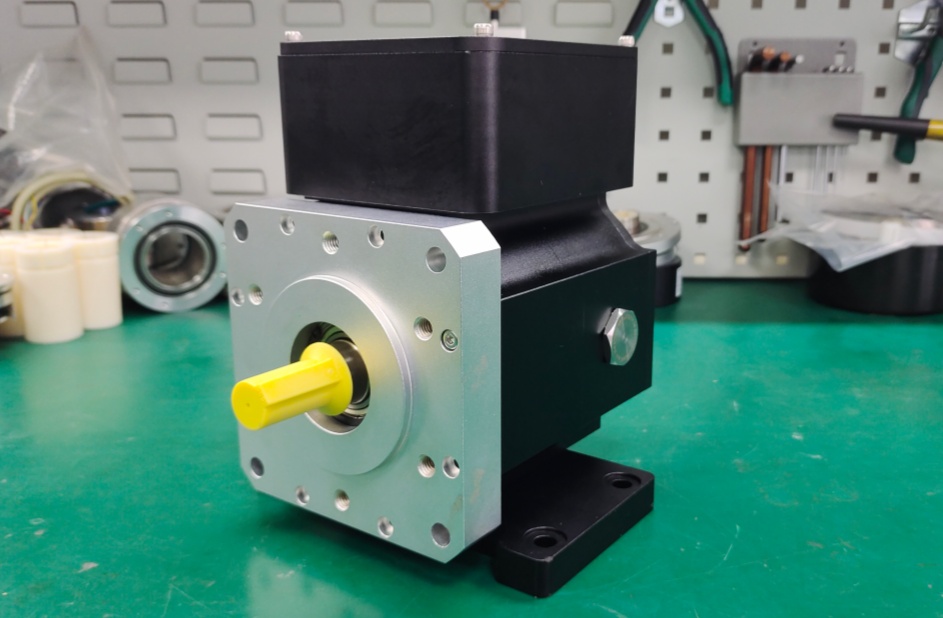

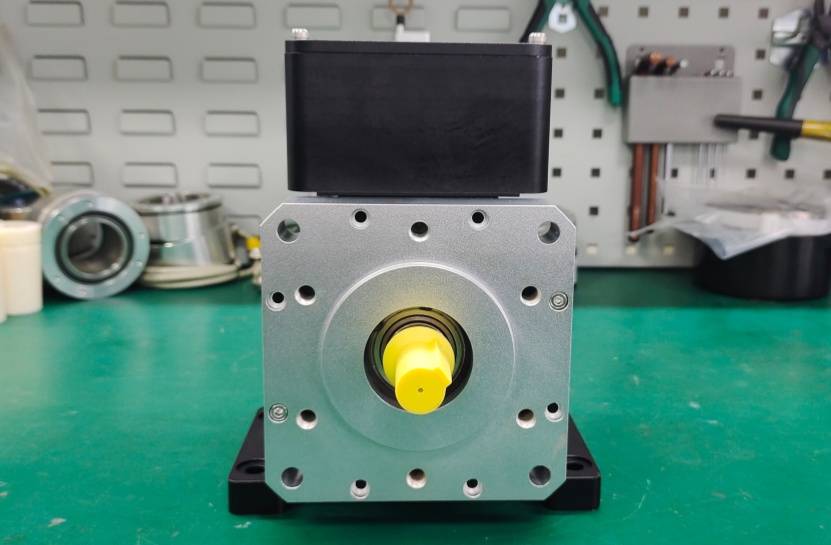

For systems originally fitted with ROD 1931 600 ID:689890-17, a 1:1 customized replacement encoder can be provided to preserve the original installation’s mechanical footprint, electrical interface, and signal behavior. This replacement is specified to match the existing shaft coupling and mounting arrangement, enabling direct integration during maintenance or retrofit without requiring changes to machine structure, control logic, or cable routing.

From an engineering standpoint, the replacement encoder is designed as an incremental rotary encoder delivering 600 pulses per revolution (PPR) to match the resolution of the original ROD 1931 600. The output signals are provided in an industrial standard format (such as HTL or TTL), ensuring compatibility with PLCs, motion controllers, and servo drives that rely on precise edge count feedback for velocity and position estimation. The electrical design supports the typical industrial DC supply voltage range and maintains signal integrity over standard cable distances. The replacement encoder’s mechanical design mirrors the original ROD 1931 series dimensions, including shaft interface and mounting footprint, allowing for a straightforward mechanical swap without additional adapters or redesign.

Mechanically, the replacement emphasizes robust performance in industrial environments. Reinforced bearings and a rugged housing support continuous operation at elevated shaft speeds while resisting vibration and shock commonly encountered on production equipment. With electrical and mechanical compatibility aligned to the original unit, the ROD 1931 600 (ID:689890-17) replacement encoder delivers dependable incremental feedback for motion control systems where accurate rotational data is essential for closed-loop control and process reliability.

Technical data

| Parameter | Specification |

| Model | ROD 1931 |

| Incremental signals | HTLs - C |

| Output pulse * | 600, 1024, 1200, 2400 |

| Scanning frequency | ≤100 kHz |

| Edge separation $a$ | ≥ 0.62 μs |

| System accuracy | ± 1/10SP |

| Power supply | 10.8V to 16.5V |

| Current consumption (without load) | ≤ 70 mA |

| Source / Sink max. | ≤ 40 mA |

| Electrical connection | Terminal board |

| Shaft | Solid shaft D = 15 mm |

| Mech. permissible speed n | ≤ 4000 min^-1} |

| Starting torque (at 20°C) | ≤0.05 Nm |

| Moment of inertia of rotor | 2.5⋅10−5 kgm^2 |

| Shaft load | Axial: 100 N, Radial: 100 N |

| Vibration (25 to 200 Hz) | ≤100 m/s^2 (JIS C 60 068-2-6, EN 60 068-2-6) |

| Shock (6 ms) | ≤1000 m/s^2 (JIS C 60 068-2-27, EN 60 068-2-27) |

| Max. operating temp. | 70°C |

| Min. operating temp. | -20°C |

| Protection EN 60 529 | IP66 |

| Weight | Approx. 4.5 kg |