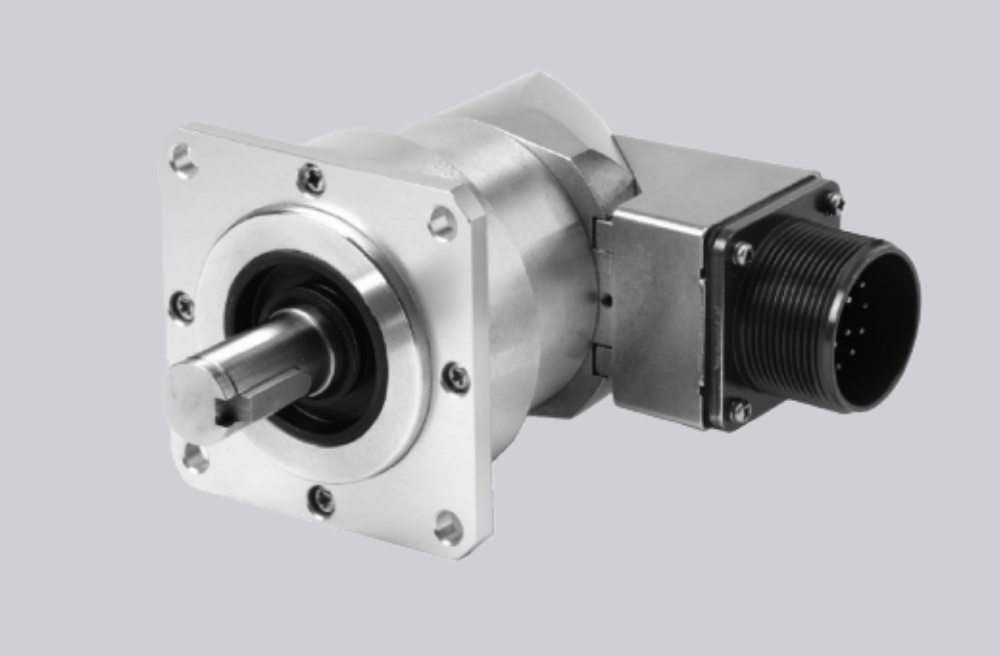

We provide a 1:1 replacement solution for the HOG 163 DN 1024 I 38H7 absolute encoder. This encoder offers 1024 pulses per revolution (PPR) resolution and operates on the Profibus-DP communication protocol, ensuring precise and reliable position feedback for demanding industrial applications. The encoder’s optical sensing technology ensures accurate data transmission even in harsh environments.

The 38H7 hollow shaft design allows for easy integration into existing systems, maintaining compatibility with standard flange sizes and drive components. With an operating voltage range of 9–30 V DC and IP56 protection, this encoder offers robust durability and resistance to environmental factors like moisture and dust. It supports a mechanical speed of up to 6000 rpm and works in temperature ranges from –40°C to +85°C.

This 1:1 replacement guarantees seamless integration and high performance with minimal downtime, making it an ideal solution for continuous, accurate position monitoring in automated systems.

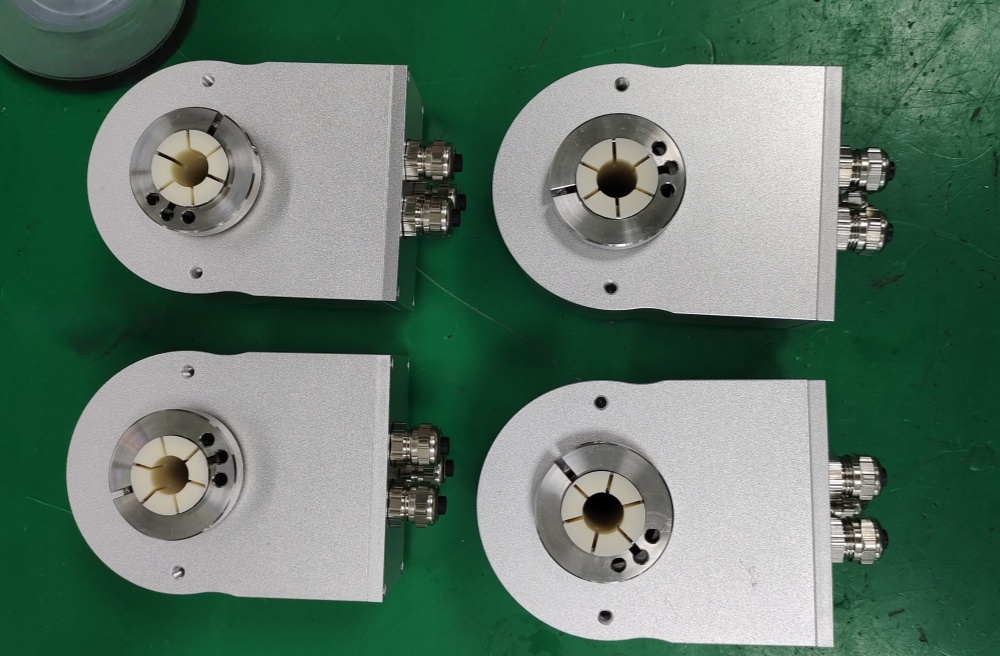

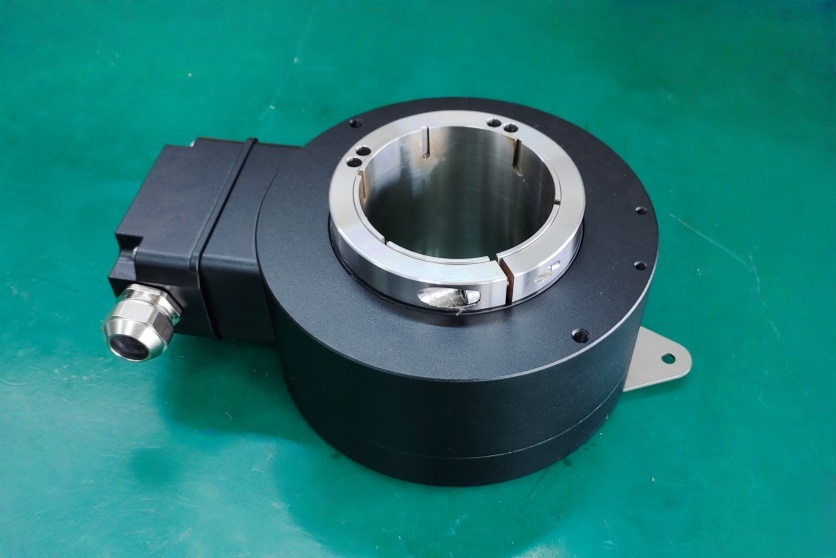

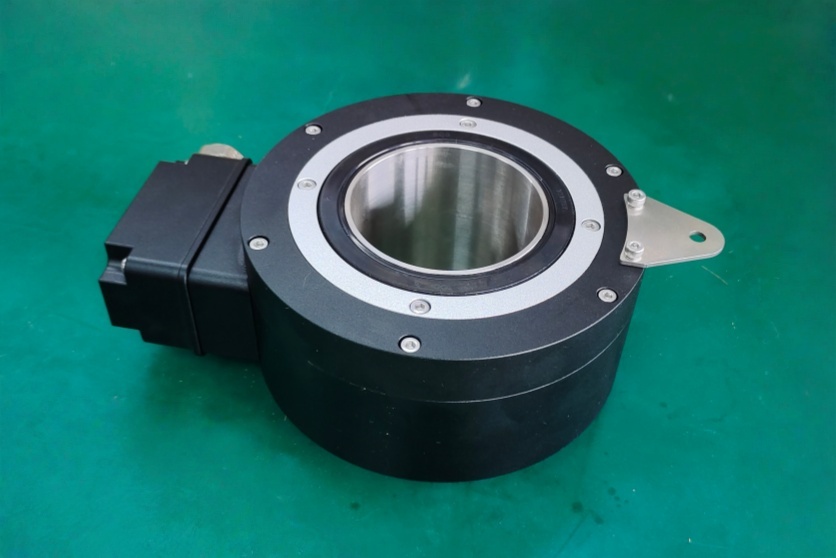

We provide HOG163 DN 1024 I 38H7 encoder replacement solutions, the use of non-standard form for the production of alternative products, the application parameters of all 1:1. Perfect replacement of the prototype encoder, to solve the procurement and other challenges. The picture is the real photo of the replacement solution.

Technical data - electrical ratings

| Technical data - electrical ratings | |

|---|---|

| Voltage supply | 9...30 VDC 5VDC+5% 9...26 VDC |

| Consumption w/o load | ≤100mA |

| Pulses per revolution | 250...5000 |

| Phase shift | 90°土20° |

| Duty cycle | 40...60% |

| Reference signal | Zero pulse, width 90° |

| Sensing method | Optical |

| Output frequency | S120kHz |

| Output signals | K1, K2, KO +inverted |

| Output stages | HTL |

| TTL/RS422 | |

| Interference immunity | EN61000-6-2 |

| Emitted interference | EN61000-6-3 |

| Approval | CE |

| UL approval/E217823 |

Technical data - mechanical design

| Technical data - mechanical design | |

|---|---|

| Size (flange) | 158 mm |

| Shaft type | a38...75m (through hollow shaft) |

| Admitted shaft load | ≤350 N axial,≤500 N radial |

| Protection EN 60529 | IP56 |

| Operating speed | S6000 rpm(mechanical) |

| Operating torque typ. | 17 Ncm |

| Rotor moment of inertia | 28.5 kgcm²(a50) |

| Material | Housing: aluminium allo Shaft: stainless steel |

| Operating temperature | -40..+85℃ |

| Resistance | IEC60068-2-6 Vibration 10g, 10-2000 Hz IEC 60068-2-27 Shock 100 g,6ms |

| Corrosion protection | IEC 60068-2-52 Salt mist for ambient conditions C4 according to ISO12944-2 |

| Explosion protection | Il3G Ex ec IIC T4 Gc (gas) Il 3D Extc II 15CDc(dust) (only with option ATEX) |

| Connection | Terminal box 2x terminal box (with option M) |

| Weight approx. | 5.4kg (048) 3.5kg (075) 3.9 kg (a75 with option M) |