For installations originally using the M6C-4S8HX51-W003 incremental encoder, a customized replacement encoder can be supplied to match the original mechanical and electrical interface. The replacement is engineered to fit the same shaft configuration, mounting dimensions, and signal output characteristics, allowing direct integration into existing equipment without changes to wiring or control logic. This approach supports efficient maintenance and retrofit work where system downtime must be minimized.

From a technical standpoint, the replacement encoder is designed for incremental position feedback with configurable pulse output up to 1024 PPR, ensuring compatibility with standard motion controllers and PLC inputs. The encoder housing and internal structure are reinforced to tolerate severe shock and vibration, making it suitable for heavy-duty industrial environments. Certified for ATEX and IECEx Zone 1, the encoder provides explosion protection without requiring intrinsic safety barriers, simplifying system design. The sealed construction offers resistance to dust, water, oil, and other contaminants, while built-in protection against wiring errors enhances operational safety in the field.

This M6C-4S8HX51-W003 replacement solution is commonly applied in harsh-environment applications such as oil and gas drilling equipment, mills, conveyors, and heavy motion control systems where reliable incremental feedback and certified explosion protection are mandatory.

Introduction

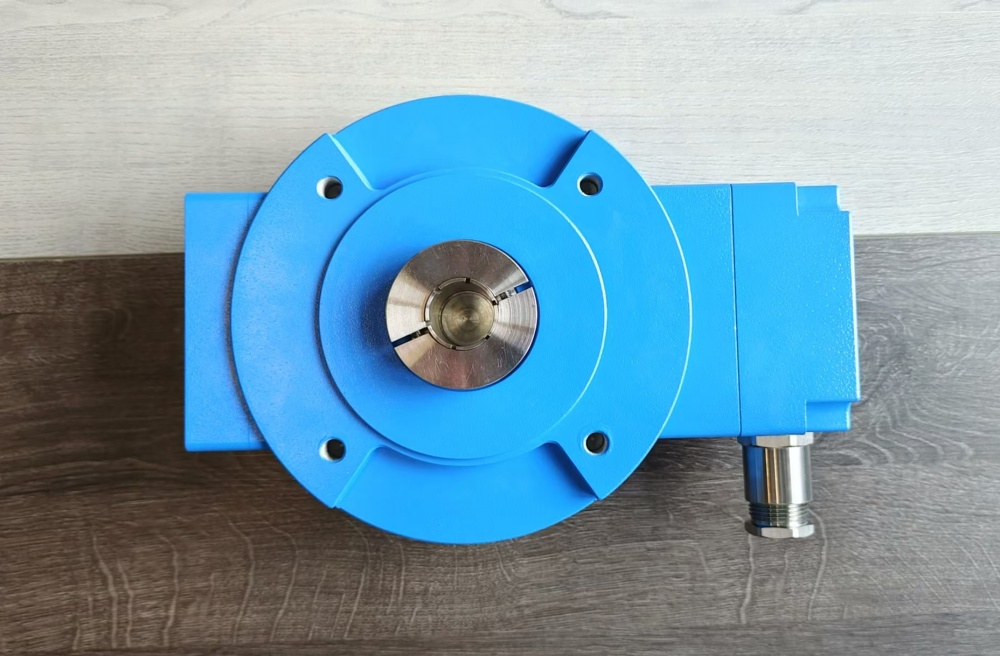

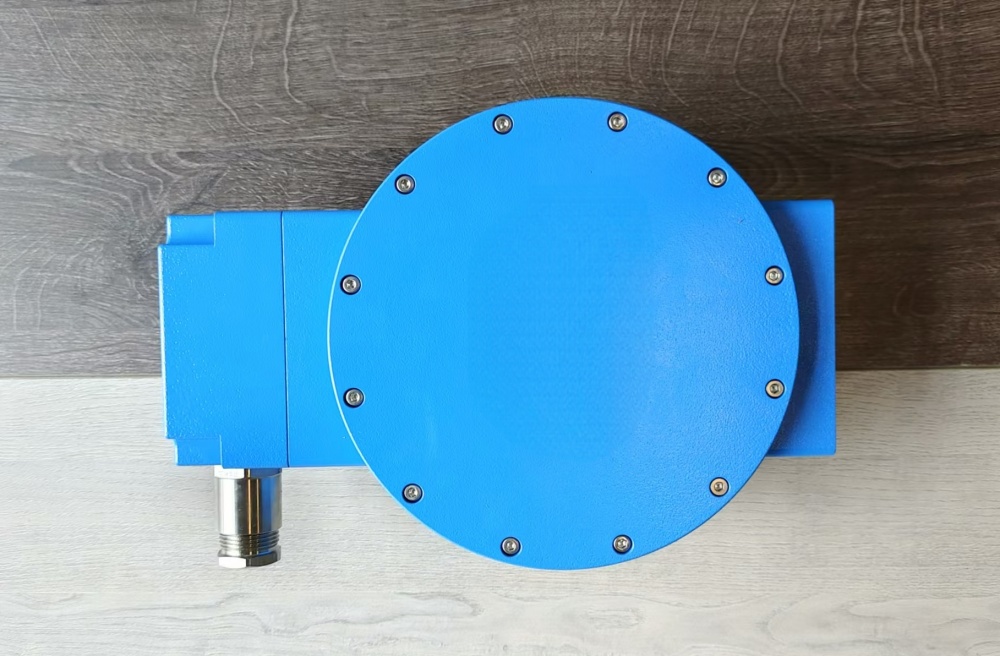

M6C Explosion-Protected Rotary Encoder for Severe Duty Applications

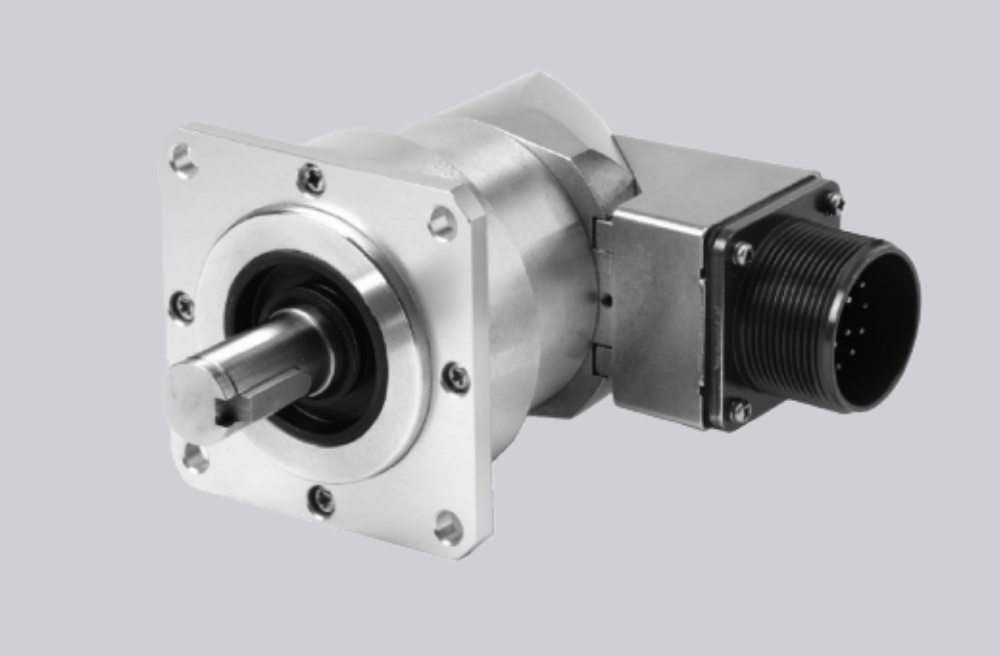

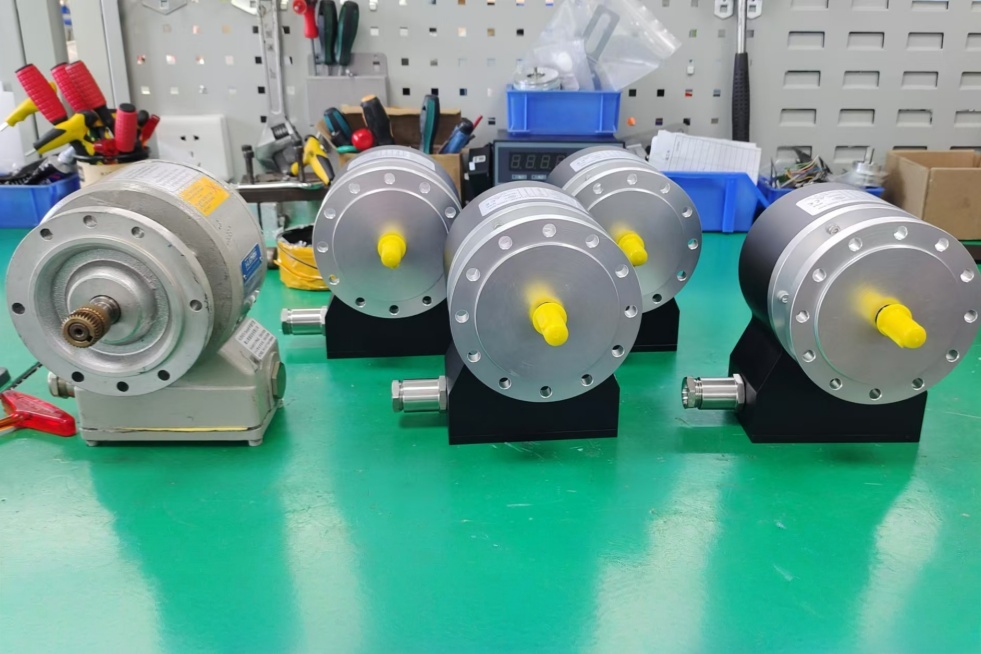

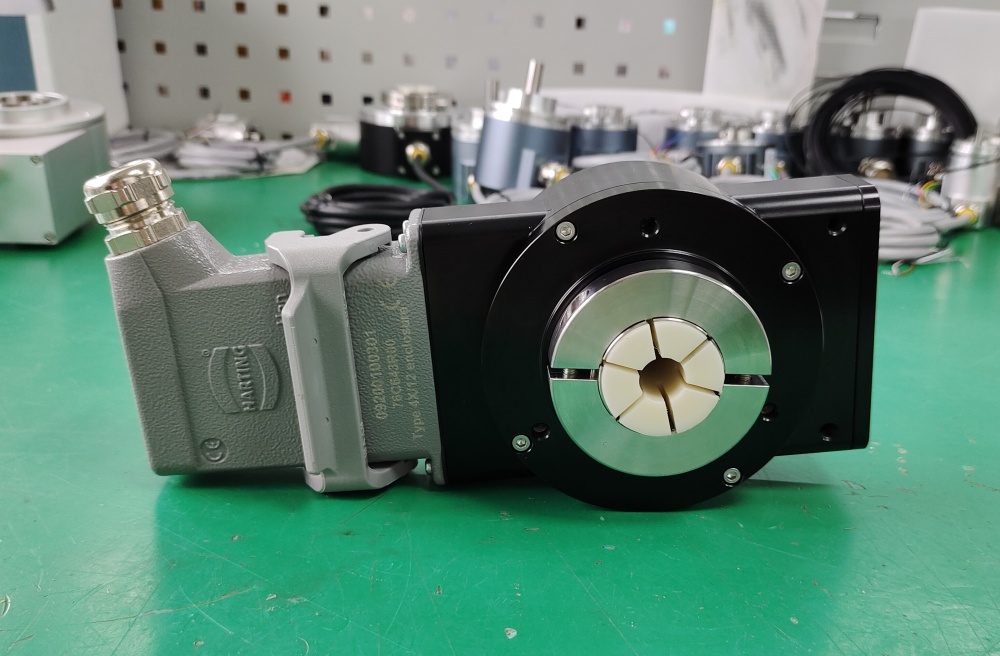

The M6C rotary encoder is designed for direct installation on motor or load shafts with diameters ranging from 1 inch to 1-1/8 inch (25–30 mm). It is certified for ATEX and IECEx Zone 1 environments and intended for use in severe mill and drilling applications where explosion protection and mechanical robustness are required.

As an updated replacement for the earlier M6 series, the M6C maintains full mechanical compatibility while adding IECEx certification. The encoder can be installed directly in ATEX or IECEx Zone 1 locations without the use of intrinsic safety barriers or external isolators, simplifying system design and reducing installation complexity.

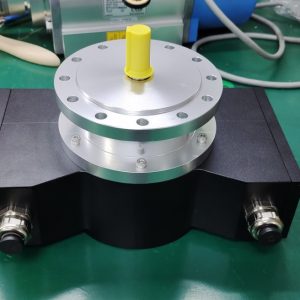

Instead of optical sensing, the M6C utilizes a magnetic sensing principle combined with a solid metal rotor, improving resistance to shock, vibration, and contamination. The sealed construction is resistant to moisture and particulate ingress, supporting continuous operation in harsh environments. Hollow-shaft, tethered configurations allow the encoder to be mounted directly onto the shaft without flanges, couplings, or reducers. Installation requires no mechanical modification—mounting is completed by sliding the encoder onto the shaft and securing the tether arm. Heavy-duty bearings are used to tolerate shaft runout and vibration commonly encountered in drilling and mill applications.

In addition, the M6C incorporates a comprehensive wiring protection design, allowing it to withstand common wiring faults and maintain signal integrity over long cable runs.

The M6C is suitable for oil and gas drilling equipment and other hazardous-area applications where explosion protection, mechanical durability, and reliable rotary position feedback are critical.

Parameters

Operating Power: Volts: 5-24 VDC; Current: 120mA, no load

Output Format: A, /A, B, /B; Optional Marker Z, /Z

Frequency Range: 0 to 250 kHz @ 6 V & 1 meter cable

PPR: 240-1200

Speed: 5000 RPM Max. Std.

Temperature: 80°C to -40°C (-40°C optional, -20°C standard)

Chemical: Polyurethane enamel paint protects against salt spray, mild acids, and bases

Enclosure Rating: IP66

Explosion Protection:

ATEX 0539 II 2 G Ex d e IIB T4 Gb

(Tamb = -40/-20°C to +80°C)

IECEx Ex d e IIB T4 Gb

(Tamb = -40/-20°C to +80°C)

Weight: 18 lbs. / 8kg.

All dimensions are in inches [millimeters].

Specifications and features are subject to change without notic