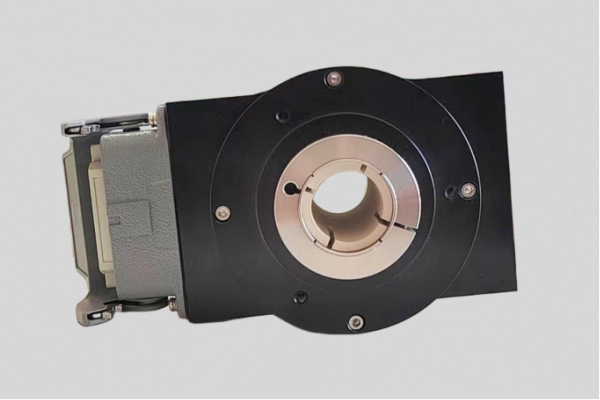

For applications using the AMG11P29Z0 absolute encoder, it is possible to provide compatible alternative solutions or custom-built replacements that maintain the same electrical interface, communication protocol, and mechanical dimensions. This ensures that existing control systems can continue operating without major redesign or software modification.

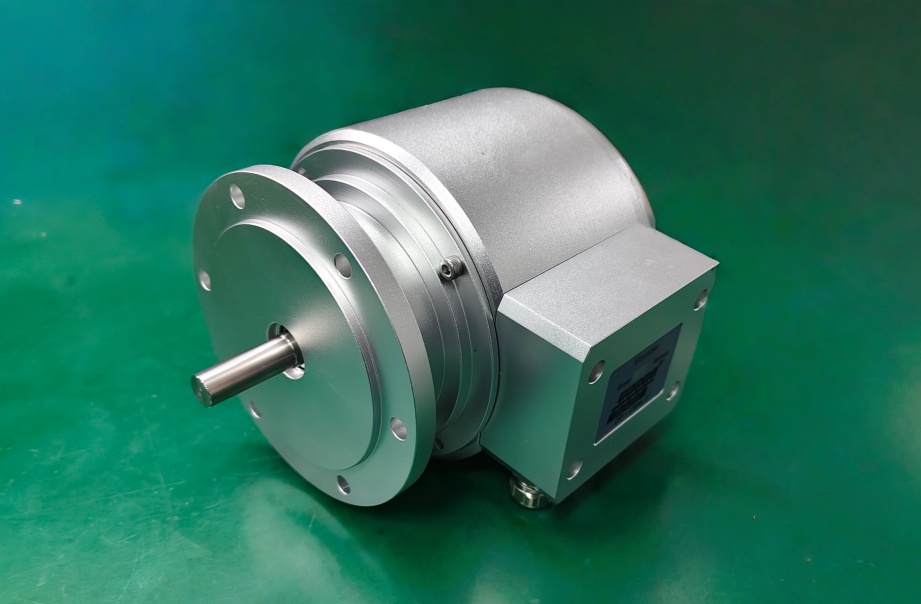

The AMG11P29Z0 has long been used in demanding industrial environments, especially in steelmaking and metallurgical equipment. Many enterprises originally selected this encoder through formal technical evaluations and project bidding processes, and it has since become a stable and well-understood component within their automation systems. As a result, it has been deeply integrated into both hardware layouts and control logic.

In recent years, the original supply channel for this model has become unavailable, creating practical challenges for maintenance, spare parts management, and long-term equipment operation. For production-oriented industries, especially continuous-process industries such as steel and metallurgy, encoder replacement is not simply a purchasing issue—it directly affects system stability, commissioning time, and operational risk.

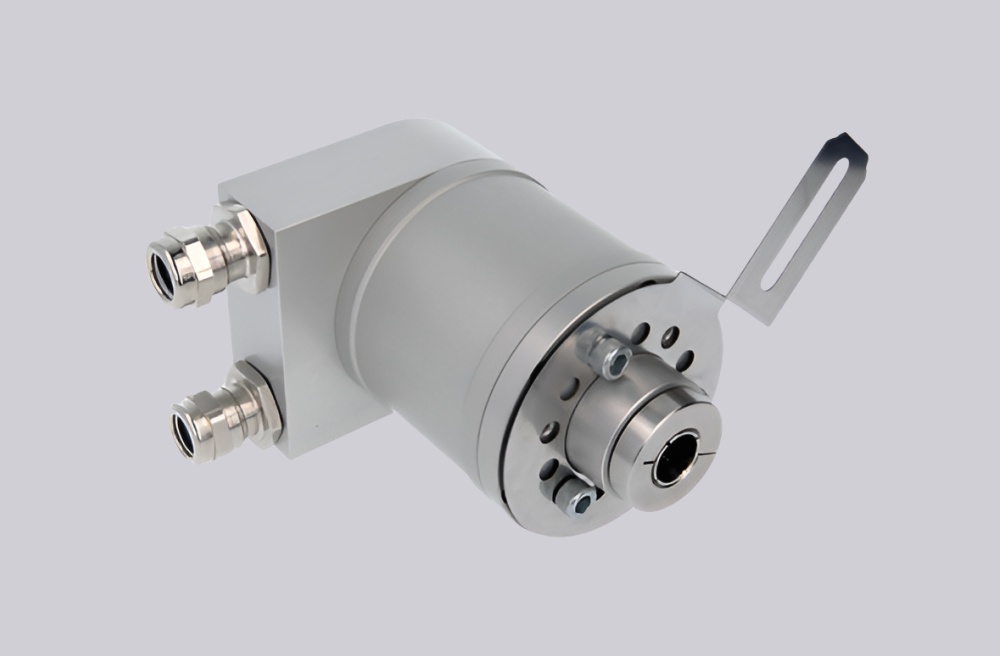

When an existing encoder model can no longer be sourced, there are generally two technical paths: selecting a compatible alternative or developing a customized replacement. While alternative models may meet the functional requirements, many users prefer to retain identical specifications. This is mainly because engineering teams are already familiar with the encoder’s behavior, signal characteristics, and installation details. Introducing a new model would require additional verification, software adaptation, and on-site testing, which increases downtime and engineering workload.

To address this situation, customized production becomes a practical and reliable solution. The AMG11P29Z0 uses a Profinet communication interface, and its application places strict requirements on resolution, response time, electrical characteristics, and environmental robustness. Based on these parameters, customized encoders can be developed to fully match the original performance, ensuring seamless integration with existing PLC and motion control systems.

Recently, several metallurgical enterprises have commissioned custom versions of this encoder for retrofit and spare-part purposes. Through detailed parameter matching and protocol-level verification, the customized units achieved stable operation in real production environments, meeting both technical and reliability expectations.

For users facing similar challenges with the AMG11P29Z0 or other absolute encoder models, customized replacement and technically equivalent alternatives can be evaluated based on application conditions, installation constraints, and control system requirements. This approach helps extend equipment lifecycle while maintaining operational continuity and engineering confidence.