PEPPERL+FUCHS PSS58N-F2AAGR0BN-0013/PSS58N-F3AAGR0BN-0013 Custom Replacement.

We can customize the production of encoder products with the same parameters, communication protocol: profinet. 1:1 customized replacement products.

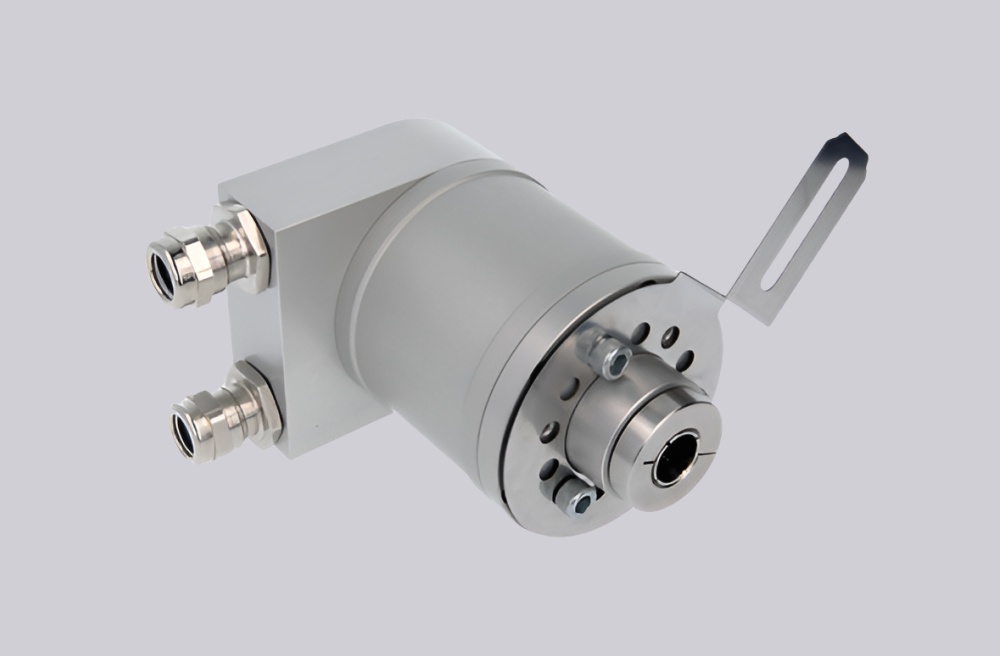

Industrial standard housing ∅58 mm

< PROFIBUS interface

< 16 Bit singleturn

< Speed transfer

< Extended scaling functions

< Programmable limit switches

< Commissioning mode

< Recessed hollow shaft

This PSS58N-type absolute encoder can be custom-manufactured as a 1:1 parameter-matched replacement based on the original mechanical and electrical specifications. The encoder uses a standard ∅58 mm industrial housing with a recessed hollow shaft design and supports PROFINET industrial communication.

The device features a 16-bit single-turn absolute position output and complies with the encoder profile requirements commonly used in industrial automation systems. It supports position data transmission, diagnostic functions, and configurable code direction. Advanced functions such as speed feedback, extended scaling, programmable limit switches, and commissioning mode are available through parameter configuration.

The encoder is suitable for applications requiring stable absolute position feedback, including motion control, machinery automation, and process equipment. Custom flange dimensions, shaft interfaces, and electrical parameters can be provided to ensure seamless integration into existing system