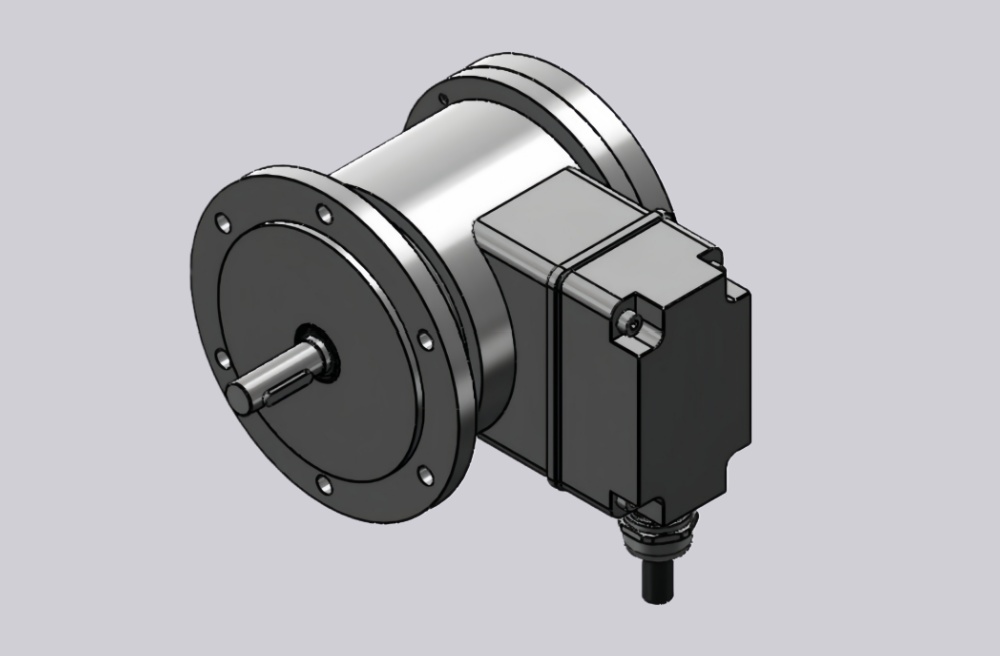

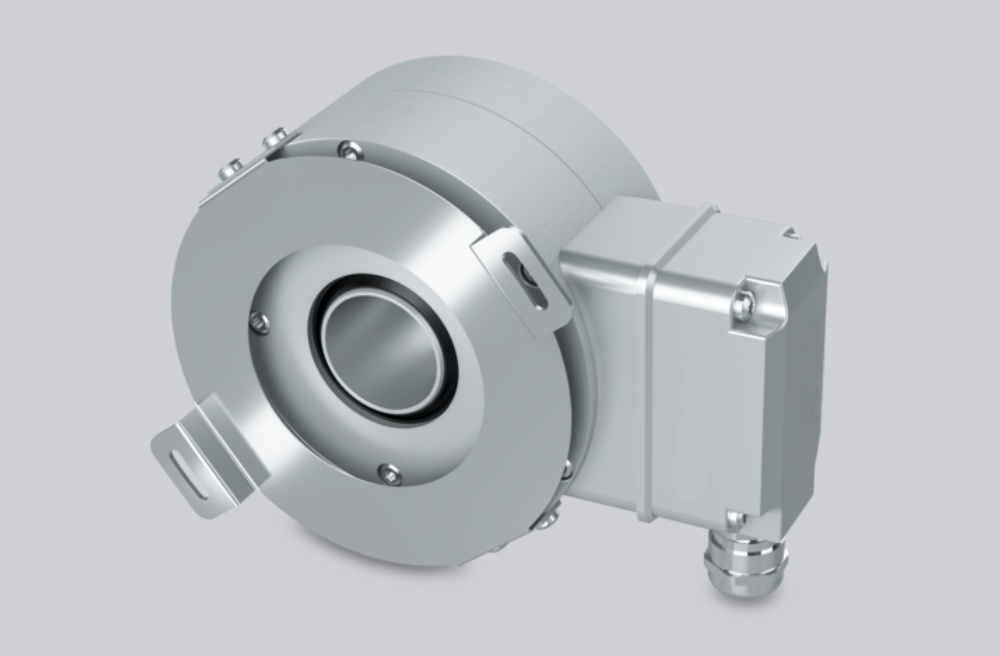

The HOG131 DN 3072 I 25H7 is a high-resolution incremental encoder designed for heavy-duty industrial drive systems. With 3072 pulses per revolution and a 25H7 hollow shaft, this model is typically installed on large motors and rotating machinery where accurate speed feedback and long-term mechanical stability are essential.

In many steel, cement, and bulk material handling applications, this encoder has been in service for years as part of a proven control setup. When the original unit becomes difficult to source, switching to a different encoder type often introduces alignment issues or signal incompatibility, especially in torque-supported installations.

For this reason, we offer a customized replacement solution. The alternative encoder maintains the same mounting interface, pulse resolution, output signals, and electrical characteristics as the original unit.

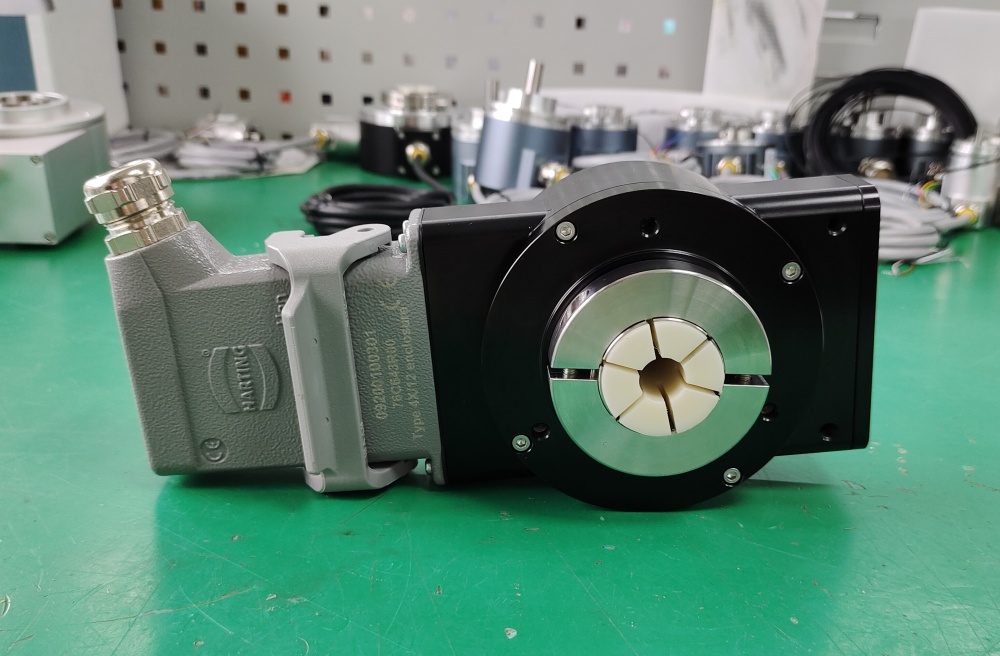

The main difference is that the replacement encoder uses a blind hollow shaft design, whereas the original encoder features a through hollow shaft. In wind power applications, this design difference does not affect functionality and allows for direct substitution.

Customers only need to inform us of the shaft length in advance, and the shaft bore depth will be matched accordingly during production.

Technical data

| Parameter | Value |

| Technical data - electrical ratings | |

| Voltage supply | 9...30 VDC; 5 VDC ±5 %; 9...26 VDC |

| Consumption w/o load | ≤100 mA |

| Pulses per revolution | 1024...3072 (other pulse numbers on request) |

| Phase shift | 90° ±20° |

| Duty cycle | 40...60 % |

| Reference signal | Zero pulse, width 90° |

| Sensing method | Optical |

| Output frequency | ≤120 kHz |

| Output signals | K1, K2, K0 + inverted |

| Output stages | HTL; TTL/RS422 |

| Interference immunity | EN 61000-6-2 |

| Emitted interference | EN 61000-6-3 |

| Technical data - mechanical design | |

| Size (flange) | ø130 mm |

| Shaft type | ø16...36 mm (through hollow shaft) |

| Admitted shaft load | ≤300 N axial; ≤500 N radial |

| Protection EN 60529 | IP 56 |

| Operating speed | ≤6000 rpm (mechanical) |

| Operating torque typ. | 15 Ncm |

| Rotor moment of inertia | 4.9 kgcm² (ø32) |

| Material (Housing) | Aluminium alloy |

| Material (Shaft) | Stainless steel |

| Operating temperature | -40...+100 °C |

| Resistance (Vibration) | IEC 60068-2-6 (10 g, 10-2000 Hz) |

| Resistance (Shock) | IEC 60068-2-27 (200 g, 6 ms) |

| Corrosion protection | Salt mist CX (C5-M) according to ISO 12944-2 |

| Explosion protection | II 3 G Ex ec IIC T4 Gc (gas); II 3 D Ex tc IIIB T135°C Dc (dust) |

| Connection | Terminal box |

| Weight approx. | 4 kg |