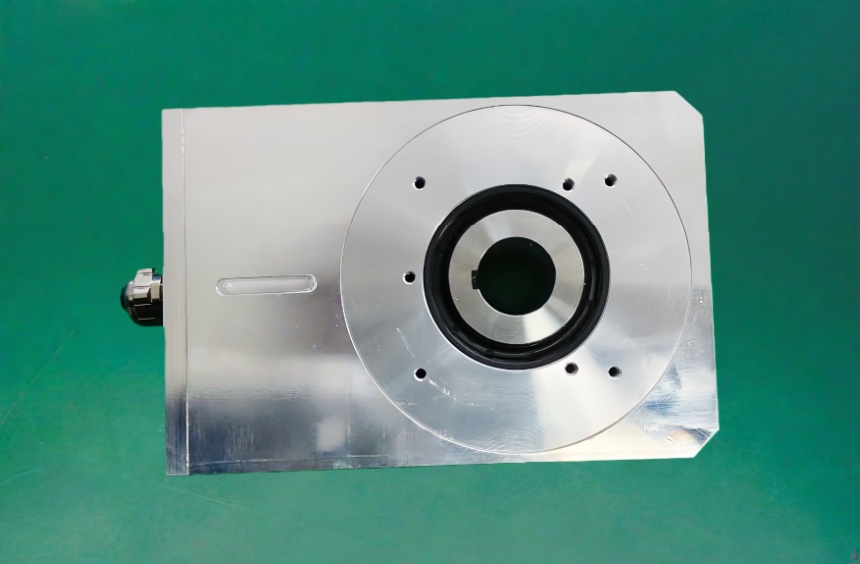

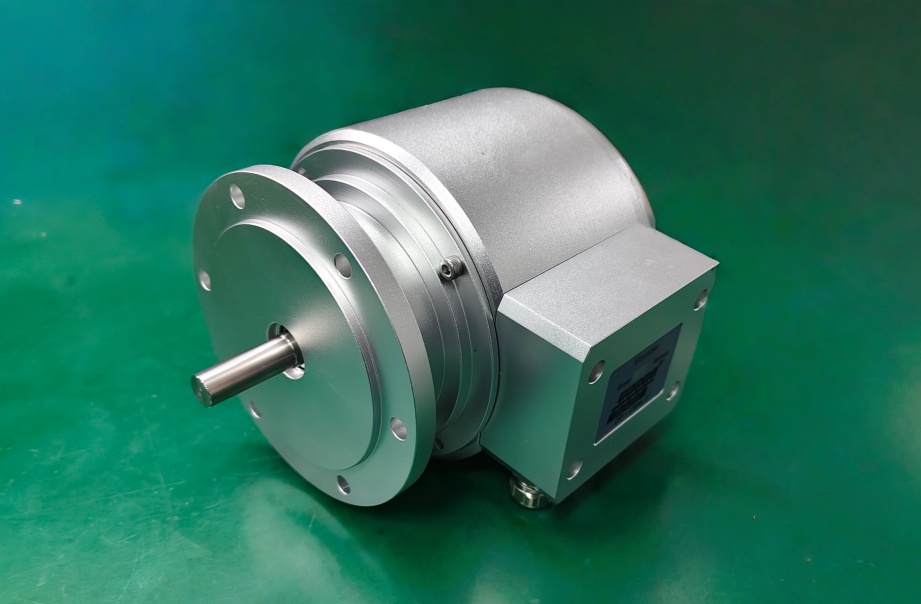

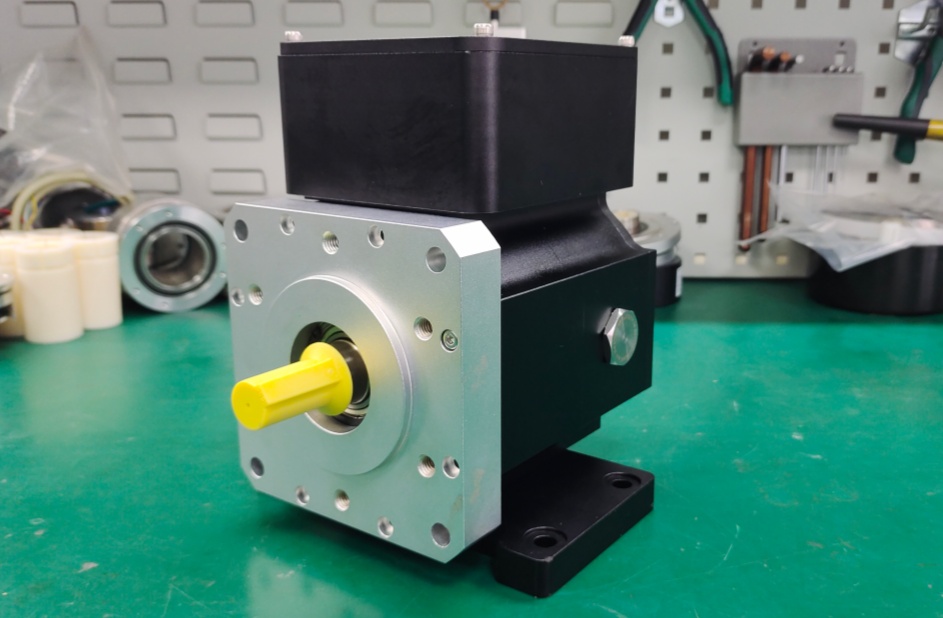

We can provide a customized 1:1 replacement solution for the HOG 10 D 1024 I incremental encoder. The replacement is designed to match the original unit in mechanical dimensions, electrical interface, and incremental signal output, allowing seamless integration into existing industrial automation systems. This solution ensures reliable feedback for motion control, positioning, and speed monitoring in applications such as heavy machinery, cranes, and steel processing equipment.

This encoder features 1024 pulses per revolution, HTL output compatible with standard industrial interfaces, and a robust optical sensing system for high precision even in harsh conditions. The unit operates on a 9–30 VDC supply and supports high-frequency signal transmission, making it suitable for both high-speed and heavy-load environments. The HOG 10 series also provides excellent shock and vibration resistance as well as IP66 protection, ensuring durability in demanding industrial applications.

As this model offers multiple shaft bore options, including Ø12 mm, Ø16 mm, Ø17 mm,and Ø20 mm hollow shafts, customers are requested to verify the correct bore size and shaft execution before placing an order to ensure proper mechanical compatibility.

Technical Data

| Parameter | Value / Description |

| Voltage supply | 9...30 VDC 5 VDC ±5 % |

| Consumption w/o load | ≤100 mA |

| Pulses per revolution | 300 ... 5000 |

| Phase shift | $90^\circ \pm 20^\circ$ |

| Duty cycle | 40...60 % |

| Reference signal | Zero pulse, width $90^\circ$ |

| Sensing method | Optical |

| Output frequency | ≤120 kHz ≤300 kHz (on request) |

| Output signals | K1, K2, K0 + inverted Error output (option EMS) |

| Output stages | HTL-P (power linedriver) TTL/RS422 |

| Shaft insulation | Suitable up to 2.8 kV |

| Transmission length | ≤350 m at 100 kHz (HTL-P) ≤550 m at 100 kHz (TTL) |

| Interference immunity | EN 61000-6-2 |

| Emitted interference | EN 61000-6-3 |

| Approval | CE UL approval / E217823 |

| Parameter | Value / Description |

| Size (flange) | ø105 mm |

| Shaft type | ø12...20 mm (blind hollow shaft) ø17 mm (cone shaft 1:10) |

| Admitted shaft load | ≤450 N axial ≤600 N radial |

| Protection EN 60529 | IP 66 |

| Operating speed | ≤6000 rpm (mechanical) |

| Operating torque typ. | 6 Ncm |

| Rotor moment of inertia | 340 gcm² |

| Material | Housing: aluminium die-cast Shaft: stainless steel |

| Operating temperature | -40...+100 °C -25...+100 °C (>3072 pulses) -50...+100 °C (optional) |

| Resistance | Vibration: IEC 60068-2-6 (20 g, 10-2000 Hz) Shock: IEC 60068-2-27 (300 g, 6 ms) |

| Corrosion protection | IEC 60068-2-52 Salt mist for ambient conditions C4 according to ISO 12944-2 |

| Explosion protection | II 3 G Ex ec IIC T4 Gc (gas) II 3 D Ex tc IIIC T135°C Dc (dust) (only with option ATEX) |

| Connection | Terminal box Terminal cover 2x terminal box (with option M) |

| Weight approx. | 1.6 kg 1.8 kg (with option M) |