Here we discuss an alternative replacement solution for the encoder model CRD58-8192R4096C2Z01, focusing on technical compatibility and practical application in industrial environments.

This topic originates from ongoing procurement challenges associated with CRD58-series encoders in certain regions, particularly within the Chinese market. While availability may vary globally, many steel and aluminum producers locally have encountered difficulties in sourcing this specific configuration for maintenance and spare-part purposes. For continuous-process industries, such supply constraints can directly affect production stability.

As an encoder solution provider, we have been commissioned by several metallurgical enterprises to develop and manufacture functionally equivalent replacement encoders matching this model. These projects are driven by real operational demand, with the goal of maintaining identical system behavior while ensuring reliable long-term supply.

Technical overview of the original configuration

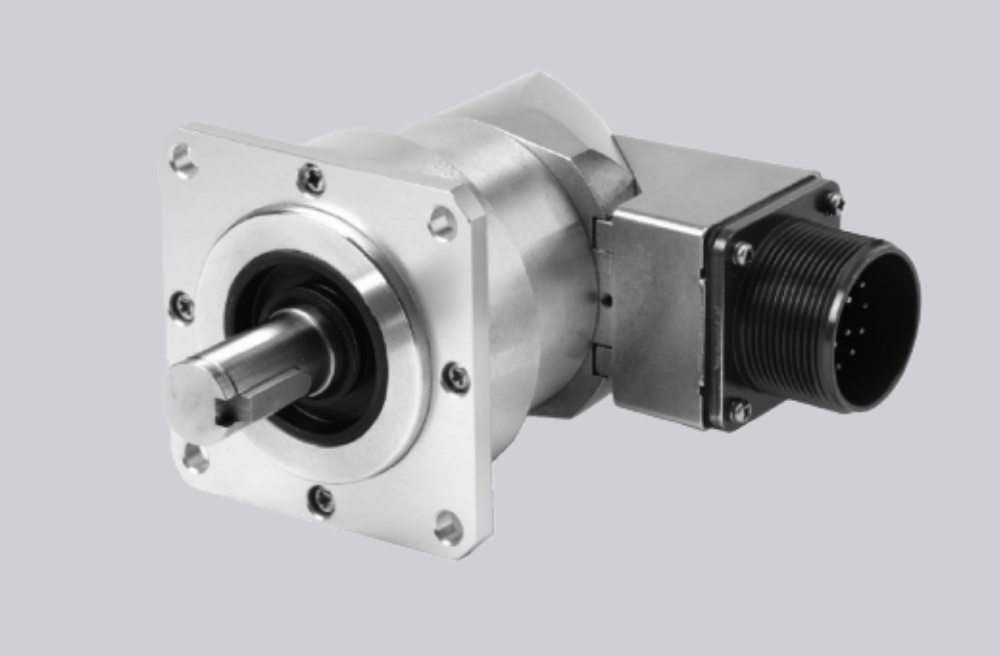

The CRD58-8192R4096C2Z01 is an absolute encoder based on the Profibus-DP communication protocol. It features a 58 mm housing diameter and is designed for shaft-mounted installation with a 6 mm shaft. Key technical parameters include:

- Resolution: up to 8192 positions per revolution

- Measuring range: up to 4096 revolutions

- Mechanical format: compact 58 mm outer diameter design

These characteristics make it suitable for precise position feedback in heavy industrial automation systems.

Replacement solution and application results

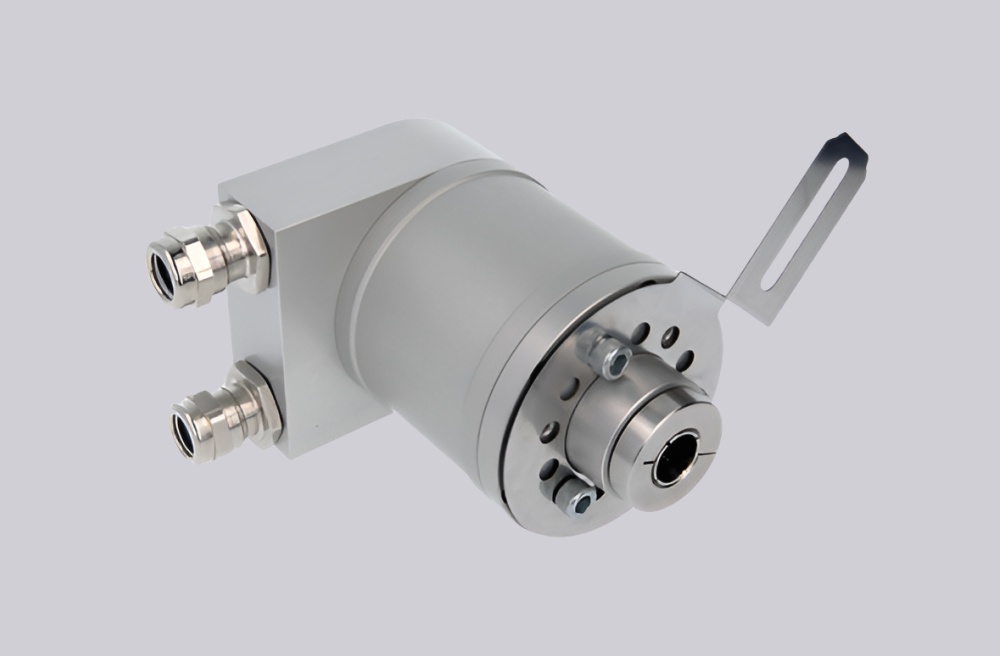

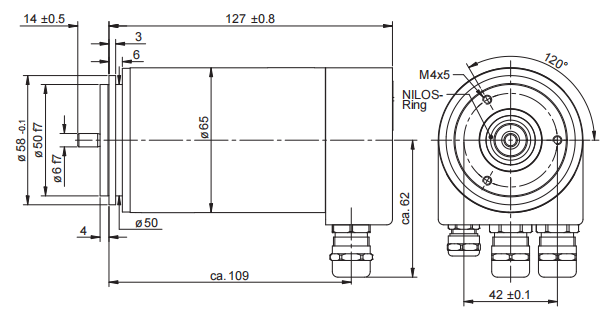

The alternative encoder solution we provide fully matches the original installation dimensions and functional parameters, ensuring direct mechanical and electrical compatibility. At the same time, the overall encoder length has been optimized, which can be beneficial in space-constrained installations.

This replacement encoder has undergone extensive testing in metallurgical production environments, where it has demonstrated high measurement accuracy, stable signal output, and reliable long-term operation under demanding conditions.

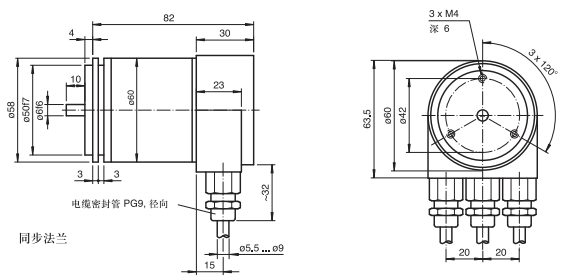

In addition, matching cable pull sensor boxes are available with measuring ranges of 2 m, 3 m, 5 m, 10 m, and beyond. These units are designed for traction-based linear measurement systems and support configurations with 6 mm shaft servo flanges or 10 mm shaft clamping flanges.

With this configuration, the replacement solution can seamlessly substitute the complete cable-pull displacement sensor assembly. In practical applications, it has delivered consistent results and proven to be well-suited to cost-sensitive industrial environments, making it a preferred option for many users seeking reliable alternatives to the original setup.