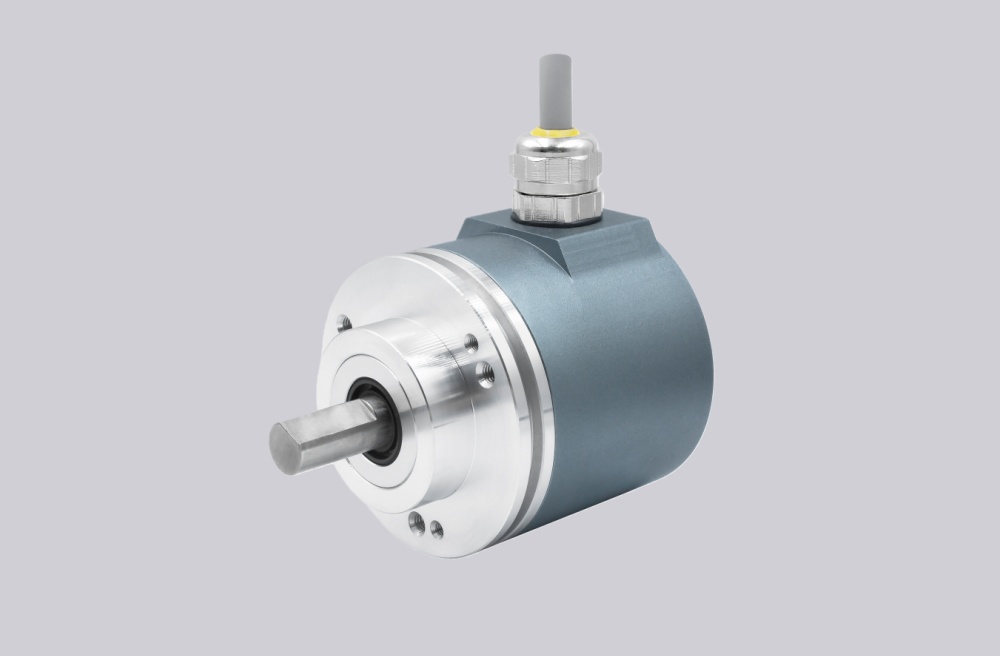

We can supply a custom-engineered replacement solution for this multi-turn absolute encoder, developed to correspond precisely with the original unit’s functional behavior and installation constraints, without direct reference to the original manufacturer. The replacement is configured according to the actual operating environment, taking into account shaft dimensions, mounting orientation, connector layout, and system voltage conditions. This ensures the encoder can be integrated into existing equipment without mechanical rework or changes to the control logic, while still allowing project-specific customization.

Technically, this encoder belongs to a class of SSI-based multi-turn absolute position sensors intended for accurate and deterministic feedback in automated machinery. The replacement maintains full compatibility with SSI Gray code communication, preserving data word length, clocking behavior, and signal integrity required by the host controller. The position information is resolved using a 4096-step single-turn resolution combined with 4096 multi-turn counts, providing a wide absolute measurement range suitable for complex motion sequences. A DC 10–32 V power supply enables reliable operation across standard industrial power infrastructures. Mechanical design parameters such as shaft interface, bearing structure, and housing geometry are aligned with the original specification to ensure stable operation at elevated rotational speeds. Where necessary, the electrical connection and output timing can be adapted to match specific PLC or motion control requirements.

In application, this customized replacement encoder is well suited for continuous-duty positioning tasks in material handling systems, lifting equipment, transfer units, and automated production lines. Its stable absolute feedback, resistance to mechanical stress, and configurable interface options make it a dependable choice for environments where accuracy, repeatability, and long-term operational stability are essential.

Technical data

| Parameter | Value | Unit |

| Max. permissible speed | 6000 | rpm^-1 |

| Permissible angular acceleration of rotor | 10^5 | rad \cdot s^-2 |

| Moment of inertia of rotor | 45 | gcm^2 |

| Max. starting torque at 25°C | 1 | Ncm |

| Max. load on shaft | ||

| - With standard shaft | axial: 50 / radial: 200 | N |

| - With expanding shaft | axial: 10 / radial: 20 | N |

| Service life of ball bearings (at 10 N axial/radial load @ 3000 $rpm^{-1}$) | 25000 | h |

| Vibration, sinusoidal 100 Hz | 100 | ms^-2 |

| Radial impacts on the flange within 10 ms | 300 | ms^-2 |

| Protection | See option concerned | - |

| Relative humidity | 95 | % |

| Temperature range | See option concerned | - |

| Weight | approx. 0.4 | kg |

| Parameter | Value | Unit |

| Max. step frequency | 100 | kHz |

| Supply voltage | 10 ... 32 | V |

| Max. power consumption | 3.7 | W |

| Angular error | $10^{-3}$ | rad |

| Pick-up code | Gray single-step | - |

| Transmitters | GaAlAs diodes | - |

| MTBF | $10^5$ | h |