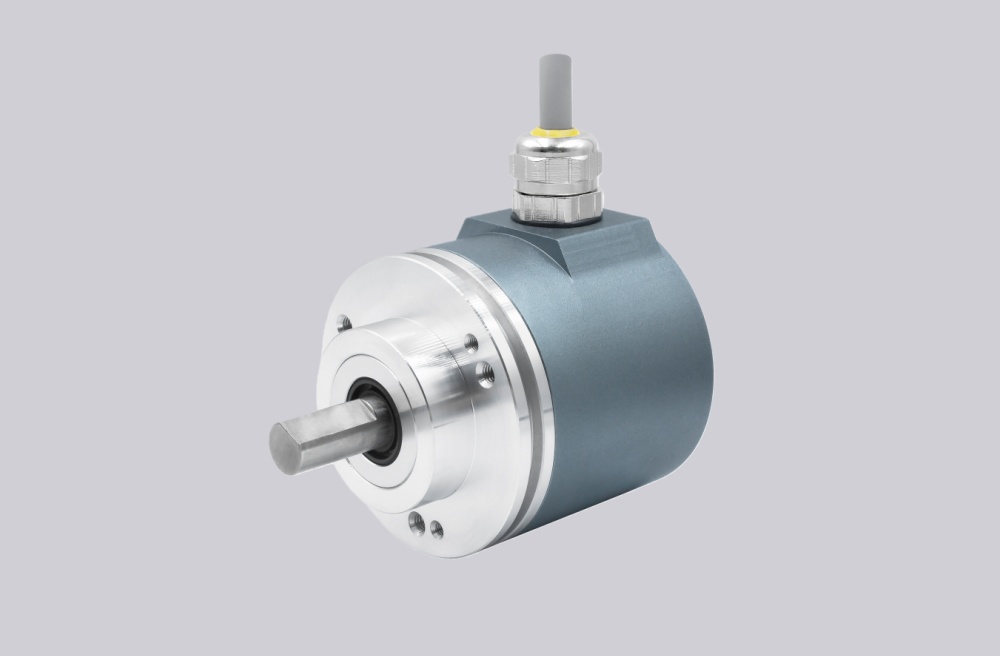

We can provide a customized replacement solution for this multi-turn absolute encoder, engineered to align with the original unit’s mechanical installation, electrical characteristics, and communication behavior, without directly referencing any brand. The replacement is configured based on the actual application environment, including shaft interface, connector orientation, housing form, and environmental requirements, ensuring functional equivalence rather than a generic substitution. This approach allows precise matching to existing control architectures while accommodating site-specific customization needs.

From a technical standpoint, the original configuration belongs to a multi-turn absolute encoder class using SSI Gray code communication, designed for deterministic position feedback in industrial automation systems. The replacement encoder maintains identical data structure and timing behavior on the SSI interface, ensuring seamless integration with existing PLCs and motion controllers. With a resolution structure of 4096 steps per revolution combined with 4096 multi-turn counts, the system delivers high-density absolute position information across the full operating range, preserving position data even after power loss. The electrical design supports a wide DC 10–32 V supply, suitable for industrial cabinets and mobile equipment where voltage stability cannot always be guaranteed. Mechanical compatibility is ensured through a matched shaft interface and housing geometry, allowing direct installation without modifying the mounting arrangement. Where required, output frequency, signal levels, and connector configuration can be fine-tuned to meet specific control or cabling standards.

In practical applications, this customized replacement encoder is suited for systems requiring reliable absolute positioning under continuous operation. Typical use cases include automated material handling, lifting mechanisms, transfer cars, and positioning axes where repeatable accuracy and resistance to vibration are essential. By combining protocol compatibility with configurable mechanical and electrical options, the replacement solution offers long-term operational reliability and predictable performance in demanding industrial environments.

Technical data

| Parameter | Value | Unit |

| Max. permissible speed | 6000 | rpm^-1 |

| Permissible angular acceleration of rotor | 10^5 | rad \cdot s^-2 |

| Moment of inertia of rotor | 45 | gcm^2 |

| Max. starting torque at 25°C | 1 | Ncm |

| Max. load on shaft | ||

| - With standard shaft | axial: 50 / radial: 200 | N |

| - With expanding shaft | axial: 10 / radial: 20 | N |

| Service life of ball bearings (at 10 N axial/radial load @ 3000 $rpm^{-1}$) | 25000 | h |

| Vibration, sinusoidal 100 Hz | 100 | ms^-2 |

| Radial impacts on the flange within 10 ms | 300 | ms^-2 |

| Protection | See option concerned | - |

| Relative humidity | 95 | % |

| Temperature range | See option concerned | - |

| Weight | approx. 0.4 | kg |

| Parameter | Value | Unit |

| Max. step frequency | 100 | kHz |

| Supply voltage | 10 ... 32 | V |

| Max. power consumption | 3.7 | W |

| Angular error | $10^{-3}$ | rad |

| Pick-up code | Gray single-step | - |

| Transmitters | GaAlAs diodes | - |

| MTBF | $10^5$ | h |