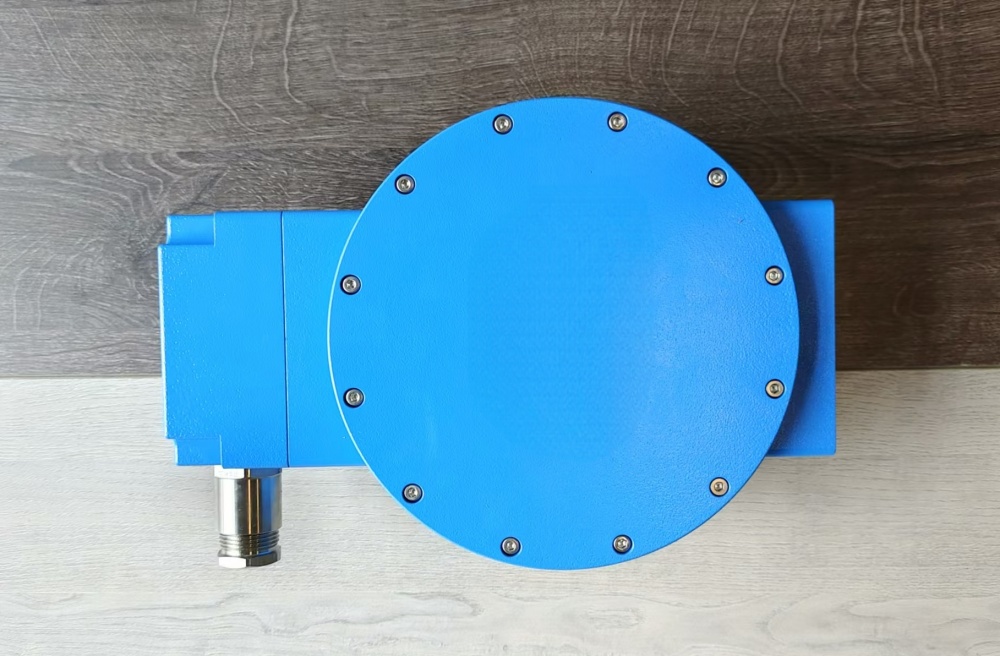

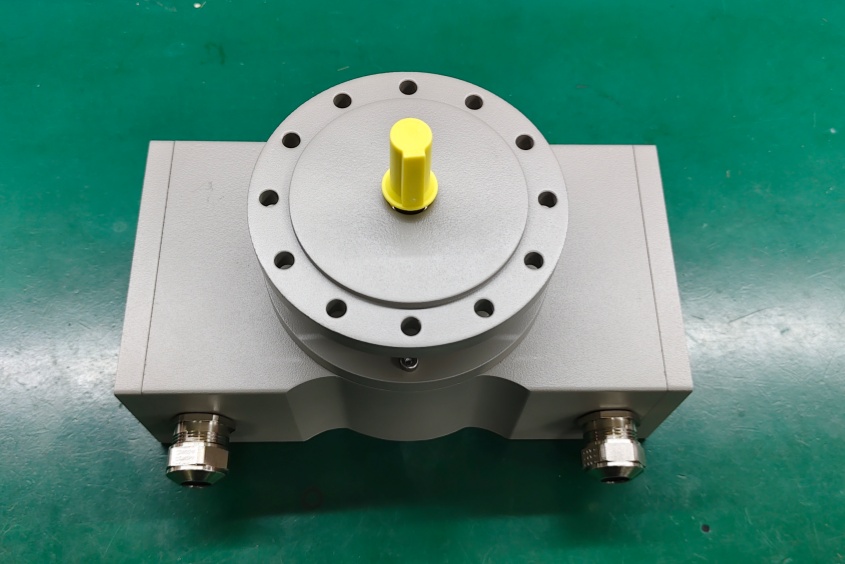

The HS35R102484P7 heavy-duty encoder has been widely recognized for its robustness and stable performance in demanding industrial applications. Due to its mechanical strength and reliable signal output, it is commonly used in environments such as heavy machinery, metallurgy, bulk material handling, and other high-load operating conditions.

In recent years, sourcing this model through standard procurement channels has become increasingly challenging in certain regions. To avoid production delays and reduce maintenance risk, several large industrial users have initiated the development of functionally equivalent alternative encoders. As a result, replacement solutions with matching parameters and operational characteristics have been introduced to support ongoing applications.

From an engineering perspective, heavy-duty encoder replacement requires careful alignment of key specifications, including resolution, output signal format, electrical interface, shaft and mounting design, enclosure strength, and environmental protection level. The available alternatives have been developed to match these critical parameters, allowing them to serve as direct substitutes without changes to the existing control system or mechanical installation.

Similar sourcing challenges have been observed not only locally but also in multiple industrial markets across Southeast Asia, including Vietnam, Indonesia, and Malaysia. In these regions, users face the same need for stable spare-part supply and long-term equipment support, particularly in continuous-operation industries.

Since the early stages of the global pandemic, these alternative encoders have already been deployed in real production environments within China. Field applications have demonstrated stable performance, consistent signal behavior, and suitability for heavy-duty operating conditions, making them a practical option for both replacement and retrofit projects.

For users who encounter procurement difficulties with the HS35R102484P7 and require a solution with the same functional parameters, technically equivalent alternatives can be evaluated based on application requirements and installation conditions. This approach helps ensure production continuity while maintaining system reliability and maintenance efficiency.